珀金斯403F-15T、404F-22、404F-22T維修保養測試調整二(英文)

詳細描述

3. Look for any leakage in the connection from the

adapter to the fuel injector (2). If leakage is visible,

make sure that the components are tightened to

the correct torque.

If leakage continues to occur, unscrew the body of

the fuel injector (2) from the nozzle nut. Inspect the

threaded surfaces for foreign particles and

damage.

If the faces are damaged, replace the fuel injector

(2).

If the faces are undamaged, clean the faces.

Repeat Steps 1 and 2. If leakage continues to

occur, replace the fuel injector.

4. Pump the pressure of the injector tester to

approximately 2030 kPa (294 psi) below the

opening pressure of fuel injector (2). Fuel should

not collect on the tip of the fuel injector (2) in a

sufficient quantity in order to drip from the tip for at

least ten seconds. A light dampness is acceptable.

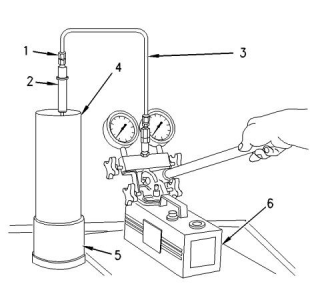

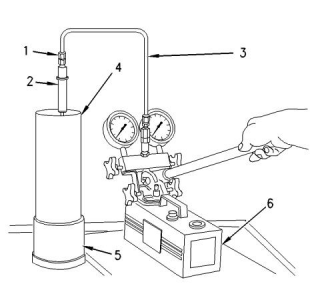

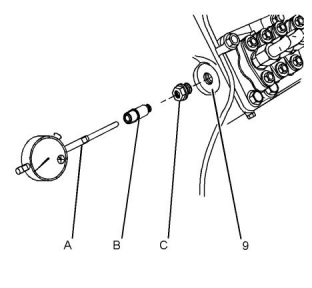

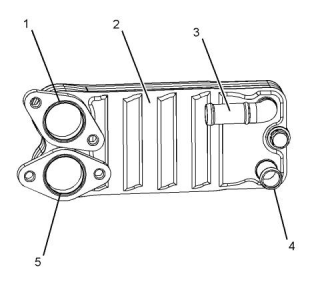

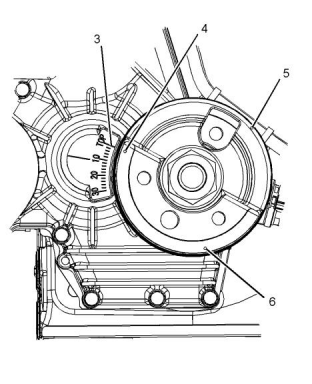

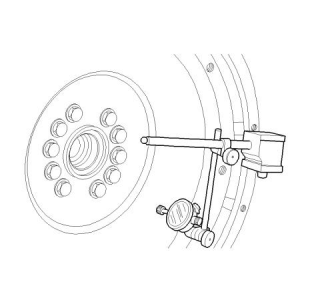

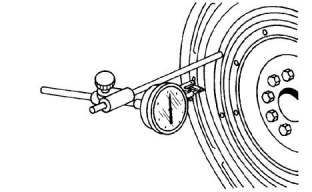

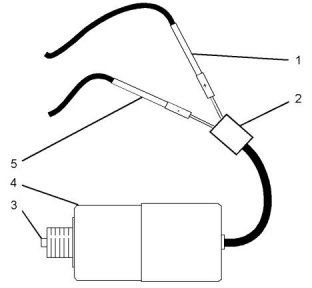

Illustration 46

g00470020

(1) Adapter

If the results of the tests are not acceptable,

replace the fuel injector (2).

(2) Fuel injector

(3) Tube Assembly

(4) Extension

(5) Fuel Collector

(6) Filter

Pressure Test

NOTICE

Do not use dirty test fluids when you test fuel injec-

tors. Also, do not test fuel injectors unless you have

the correct service tools.The use of dirty test fluids

and the use of incorrect service tools will result in

damage to the fuel injectors.

Ensure that you wear eye protection at all times

during testing. When fuel injectors are tested, test

fluids travel through the orifices of the nozzle tip

with high pressure. Under this amount of pres-

sure, the test fluid can pierce the skin and cause

serious injury to the operator. Always keep the tip

of the fuel injector pointed away from the operator

and into the fuel collector and extension.

Note: This procedure is a test of the opening

pressure of the fuel injector.

1. Connect the fuel injector (2) to suitable tooling that

is similar to the Illustration 46 .

The spray from the fuel injector (2) must be

directed into the extension (4) and the fuel

collector (5).

Use clean calibration fluid when the fuel injectors

are tested. The calibration fluid should be

equivalent to SAE J-967 (ISO 4113) oil.

2. Close the gauge protector valve. Close the shutoff

valve. Open the pump isolator valve. Flush the fuel

injector (2) by operating the nozzle tester. Operate

the nozzle tester for 10 to 15 strokes at a rate of

approximately sixty strokes per minute.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

51

Fuel System

3. Open the gauge protector valve. Slowly increase

the pressure until the valve in the fuel injector (2)

opens. Note the highest pressure indication on the

dial indicator before the pointer moves to 0 kPa

(0 psi). This highest pressure indication is the

opening pressure of fuel injector (2). The opening

pressure occurs when the valve needle is lifted

from the nozzle seat.

1. Connect the fuel injector (2) to suitable tooling that

is similar to the Illustration 47 .

Position the fuel injector (2) so that the direction of

the fuel spray is into the extension (4) and the fuel

collector (5).

2. Close the gauge protector valve and the shutoff

valve. Open the pump isolator valve.

Refer to Specifications, “Fuel Injection Nozzles” for

the correct pressure settings. If the opening

pressure is not within the range of the setting

which is given in the table, the fuel injector (2) must

be replaced.

Test for the Nozzle Spray Pattern

Ensure that you wear eye protection at all times

during testing. When fuel injectors are tested, test

fluids travel through the orifices of the nozzle tip

with high pressure. Under this amount of pres-

sure, the test fluid can pierce the skin and cause

serious injury to the operator. Always keep the tip

of the fuel injector pointed away from the operator

and into the fuel collector and extension.

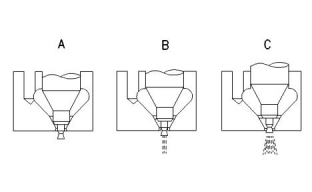

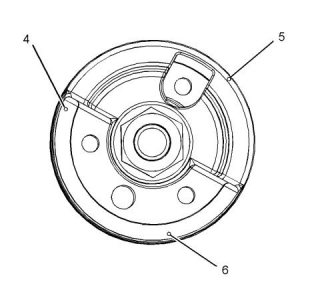

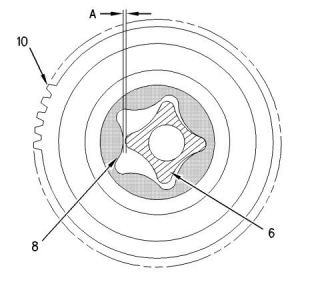

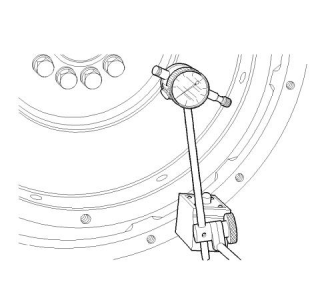

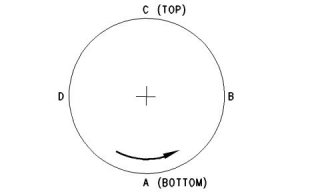

Illustration 48

g00468241

Phases of operation and spray pattern of the fuel

injector

The spray angle is 4 degrees from the vertical when

the nozzle is fully open.

(A) Closed nozzle

(B) Open nozzle

(C) Fully open nozzle

3. Quickly pump the nozzle tester and look at the

spray pattern when the fluid begins to flow through

the orifices of fuel injector (2) .

The spray flows around the tip of the nozzle. A

difference in the nozzle spray patterns indicates

that the fuel injector (2) is faulty. Refer to the

correct spray pattern in Illustration 48 .

Observe the following characteristics of the spray:

• Drops of fuel should not be in the spray.

• Fuel should be sprayed in the shape of a cone

around the nozzle.

• Fuel should be sprayed evenly in a 360 degree

pattern around the nozzle.

Illustration 47

g00470020

(1) Adapter

(2) Fuel injector

(3) Tube Assembly

(4) Extension

(5) Fuel Collector

(6) Filter

Note: Be sure that the gauge protector valve is

closed before the fuel injector (2) is removed from the

nozzle tester. Closing the valve will prevent damage

to the pressure gauge.

The pressure adjustment must be correct before you

test the spray pattern.

This procedure tests for the correct spray pattern for

the fuel injectors.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

52

KENR9144

Fuel System

i01944302

i02617170

Fuel Quality - Test

Gear Group (Front) - Time

Use the following procedure to test for problems

regarding fuel quality:

1. Determine if water and/or contaminants are

present in the fuel. Check the water separator (if

equipped). If a water separator is not present,

proceed to Step 2. Drain the water separator, if

necessary. A full fuel tank minimizes the potential

for overnight condensation.

Note: A water separator can appear to be full of fuel

when the water separator is actually full of water.

2. Determine if contaminants are present in the fuel.

Remove a sample of fuel from the bottom of the

fuel tank. Visually inspect the fuel sample for

contaminants. The color of the fuel is not

necessarily an indication of fuel quality. However,

fuel that is black, brown, and/or similar to sludge

can be an indication of the growth of bacteria or oil

contamination. In cold temperatures, cloudy fuel

indicates that the fuel may not be suitable for the

operating conditions. Refer to Operation and

Maintenance Manual, “Fuel Recommendations” for

more information.

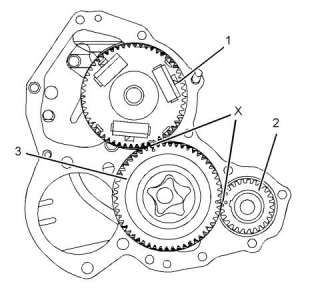

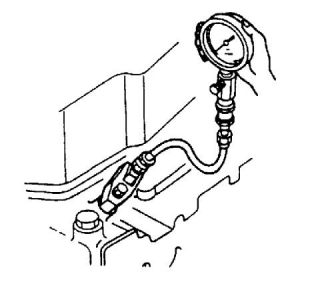

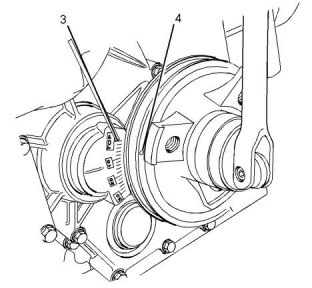

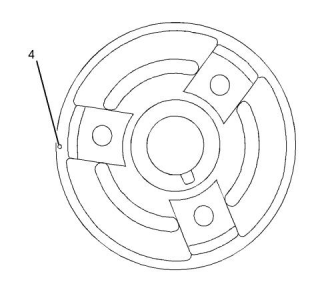

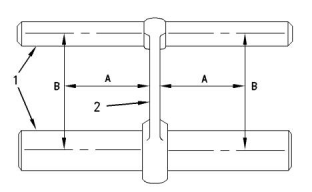

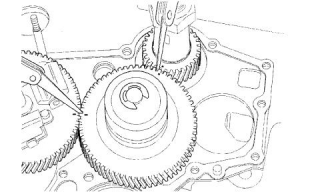

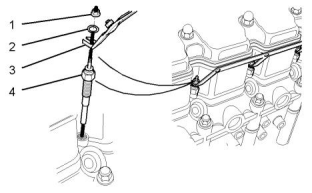

Illustration 49

g01335186

1. Align timing mark (X) on idler gear (3) with the

timing mark on crankshaft gear (2) and align timing

mark (X) on idler gear (3) with the timing mark on

camshaft gear (1).

3. If fuel quality is still suspected as a possible cause

of problems regarding engine performance,

disconnect the fuel inlet line, and temporarily

operate the engine from a separate source of fuel

that is known to be good. This will determine if the

problem is caused by fuel quality. If fuel quality is

determined to be the problem, drain the fuel

system and replace the fuel filters. Engine

performance can be affected by the following

characteristics:

i05223669

Governor - Adjust

Note: The setting of the front housing is only

necessary if the front housing is damaged or if the

front housing must be renewed.

• Cetane number of the fuel

• Air in the fuel

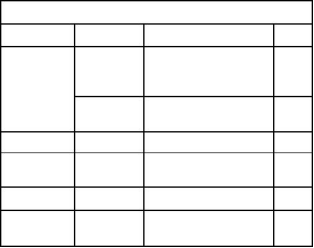

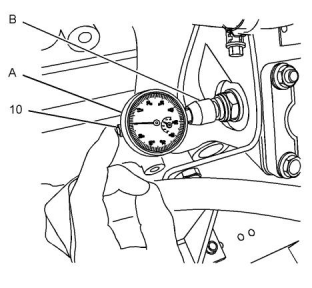

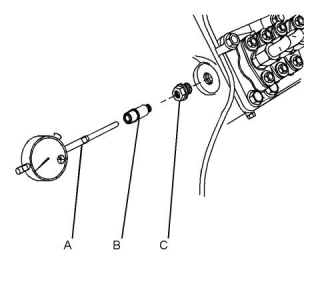

Table 3

Required Tools

Tool

Part Number

Part Description

Qty

• Other fuel characteristics

A

21825617

Dial Indicator

1

graduated in 0.01 mm

(0.0004 inch)

i04903819

Fuel System - Prime

-

Extension that is 20 mm

(0.787 inch)long

1

B

C

27610331

27610332

Dial holder

1

1

Turn the keyswitch to the ON position for 2 minutes in

order to prime the fuel system. Turn keyswitch to OFF

position, then turn to the ON position again.

Adapter for the cylinder

block

D

E

27610333

-

Calibration spring

1

1

The engine is primed and ready to start.

Allen head screw (M4 x 20

mm x 0.70)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9144

53

Fuel System

Record the Governor Settings

NOTICE

The engine must be in running condition in order to

carry out the governor adjustment procedure. If the

engine cannot be returned to a running condition con-

tact an authorized Perkins distributor

If the front housing has been removed, install the front

housing. Refer to Disassembly and Assembly,

“Housing (Front) - Install”

The setting of the low idle stop screw and the high

idle stop screw must be recorded. The settings are

recorded in order to ensure that the governor

operation is restored.

Note: Engine speed must be recorded from the

crankshaft.

1. Operate the engine until the normal operating

temperature is reached.

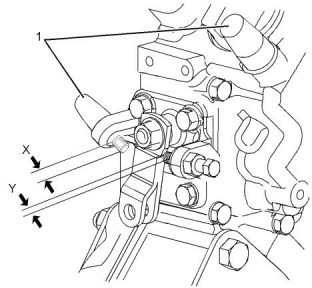

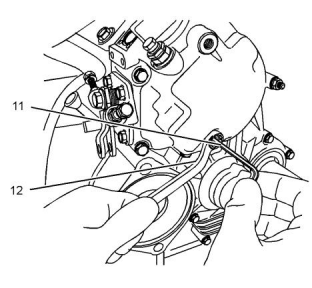

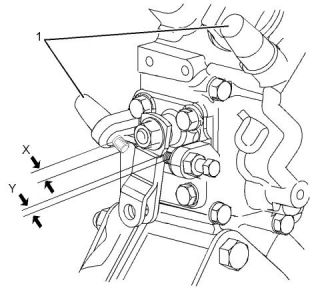

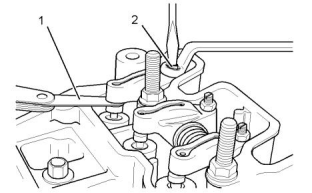

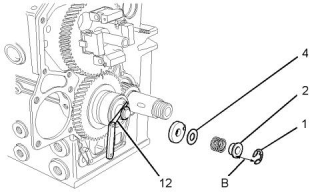

Illustration 51

g03345218

2. Operate the engine at low idle speed. Use the

electronic service tool to record the engine rpm as

“Speed B” .

Typical example

4. Remove tamper proof caps (1).

3. Accelerate the engine to high idle. Use the

electronic service tool to record the engine rpm as

“Speed A” .

5. Record Protrusion (X) of the high idle stop screw

(4).

6. Record Protrusion (Y) of the low idle stop screw

(5).

Note: The recorded “Speed B” will be lower than the

recorded “Speed A” .

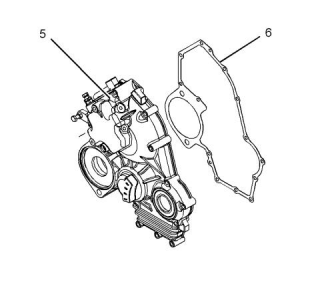

Removal of the Old Front Housing

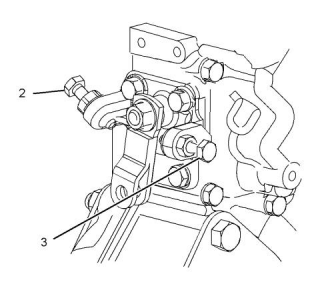

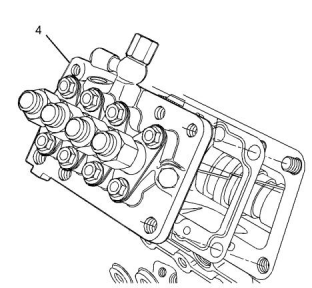

Illustration 50

g01494533

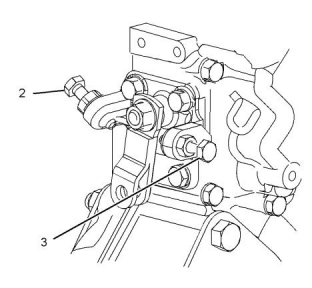

Illustration 52

g03345219

Typical example

Typical example

1. Remove fuel injection pump (4). Refer to

Disassembly and Assembly, “Fuel Injection Pump -

Remove and Install” for the correct procedure.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

54

KENR9144

Fuel System

2. Remove the crankshaft pulley. Refer to

Disassembly and Assembly, “Crankshaft Pulley -

Remove”

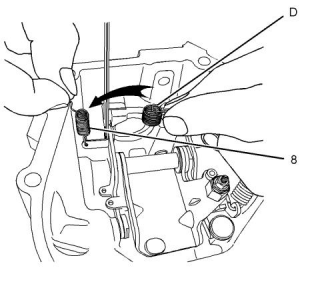

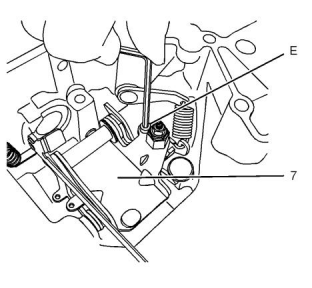

Illustration 55

g03345224

Typical example

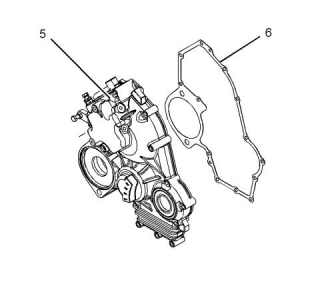

Illustration 53

g03345222

6. Remove start spring (8) and replace the start

spring with Tooling (D).

Typical example

3. Remove front housing (5). Refer to Disassembly

and Assembly, “Housing (Front) - Remove” for the

correct procedure.

7. Install the front housing. Refer to Disassembly and

Assembly, “Housing (Front) - Install” for the correct

procedure.

4. Remove the gasket (6). Ensure that the face of the

Note: Do not install a gasket.

front plate is clean.

8. Install the fuel injection pump to the cylinder block.

Install the original shim. Refer to Disassembly and

Assembly, “Fuel Injection Pump - Remove and

Install” for the correct procedure.

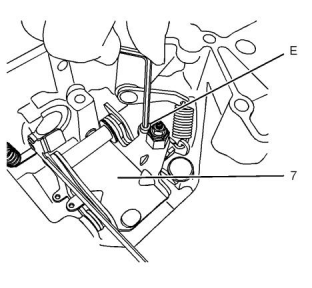

Illustration 54

g03338638

Typical example

5. Install Tooling (E) to lever assembly (7). Tighten

tooling (E) to a torque of 0.4 N·m (3.540 lb in).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

55

Fuel System

13. Push Tooling (A) into Tooling (B) for a further

2 mm (0.0787 inch). Lock Tooling (B) in order to

retain Tooling (A) in position. Set Tooling (A) to

read 2.00 ± 0.01 mm (0.0787 ± 0.0004 inch).

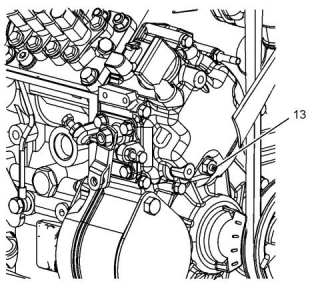

Illustration 56

g03338639

Typical example

9. Install Tooling (C) into cylinder block (9).

10. Install Tooling (B) into Tooling (C).

11. Assemble Tooling (A).

Illustration 58

g03338641

Typical example

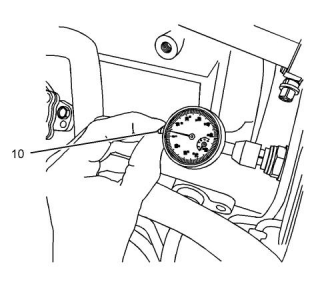

14. Push plunger (10) of Tooling (A) several times in

order to seat the rack of the fuel injection pump.

When the plunger is gently released, check that

Tooling (A) reads 2.00 ± 0.01 mm

12. Install Tooling (A) into Tooling (B) until the

extension on Tooling (A) touches the rack of the

fuel injection pump.

(0.0787 ± 0.0004 inch).

Note: If the rack of the fuel injection pump has heavy

resistance to movement, remove tooling (A). Remove

the fuel injection pump. Wash the fuel injection pump

with a suitable cleaner. Install the fuel injection pump.

Repeat steps 12, 13 and 14.

Setting the New Front Housing

Note: Do not move the position of Tooling (A), Tooling

(B), or Tooling (C) in the cylinder block.

1. Pull plunger (10) of Tooling (A) until the plunger has

reached the fully out position. Use a suitable clip to

retain the plunger in this position.

2. Remove the fuel injection pump. Refer to

Disassembly and Assembly, “Fuel Injection Pump -

Remove and Install” for the correct procedure.

3. Remove the original front housing. Refer to

Disassembly and Assembly, “Housing (Front) -

Remove” for the correct procedure.

Illustration 57

g03338640

Typical example

4. Disassemble the original front housing. Refer to

Disassembly and Assembly, “Housing (Front) -

Disassemble” for the correct procedure.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

56

KENR9144

Fuel System

5. Assemble the replacement front housing with the

parts that were removed from the original front

housing. Install a new fuel screw and a new

locknut. Refer to Disassembly and Assembly,

“Housing (Front) - Assemble” for the correct

procedure.

6. Remove Tooling (E) from the original front housing.

Install Tooling (E) to the lever assembly of the

replacement front housing. Tighten Tooling (E) to a

torque of 0.4 N·m (3.5 lb in).

7. Install the replacement front housing. Refer to

Disassembly and Assembly, “Housing (Front) -

Install” for the correct procedure.

Note: Do not install a gasket.

8. Install the fuel injection pump to the cylinder block.

Install the original shim. Refer to Disassembly and

Assembly, “Fuel Injection Pump - Remove and

Install” for the correct procedure.

Illustration 60

g03338643

Typical example

9. Remove the clip from plunger (10) of Tooling (A).

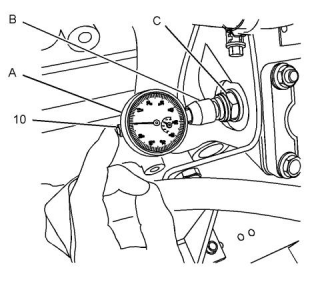

1. Release the plunger on Tooling (A). Do not move

the position of Tooling (A), Tooling (B), or Tooling

(C) in the cylinder block.

Setting the Fuel Screw

2. Use a ring spanner (Box wrench) (12) to retain the

locknut of the fuel screw in position.

3. Use an allen wrench (11) to rotate the allen head

screw. Observe the reading on the dial indicator.

Adjust the allen head screw until the indicator

reads 2.00 ± 0.01 mm (0.0787 ± 0.0004 inch).

4. Tighten the locknut to a torque of 6 N·m (55 lb in)

in order to retain the allen head screw in position.

The fuel screw is now set.

5. Ensure that the reading of Tooling (A) is

2.00 ± 0.01 mm (0.0787 ± 0.0004 inch).

Final Installationof the New Front

Housing

Illustration 59

g03338642

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

57

Fuel System

Illustration 61

g01495413

Typical example

Illustration 63

g03345222

Typical example

1. Remove Tooling (A) and Tooling (B).

2. Remove Tooling (C).

6. Install a new gasket (6). Ensure that the gasket is

clean and free from damage.

3. Remove the fuel injection pump. Refer to

Disassembly and Assembly, “Fuel Injection Pump -

Remove and Install” for the correct procedure.

7. Install the replacement front housing (5) Refer to

Disassembly and Assembly, “Housing (Front) -

Install” for the correct procedure.

4. Remove the front housing. Refer to Disassembly

and Assembly, “Housing (Front) - Remove” for the

correct procedure.

Illustration 64

g01494533

Typical example

Illustration 62

g03338638

Typical example

5. Remove Tooling (E) from lever assembly (7).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

58

KENR9144

Fuel System

Illustration 65

g03345218

Illustration 66

g03338646

Typical example

Typical example

8. Set the Protrusion (X) of the high idle stop screw

(2) to the same dimensions as the stop screws on

the original front housing.

15. Install tamper proof caps (1) to the high idle screw

(2). Install the tamper proof cap (not shown) to fuel

screw (13).

9. Set the Protrusion (Y) of the low idle stop screw (3)

to the same dimensions as the stop screws on the

original front housing.

Note: Care should be taken when the tamper proof

cap is installed to the fuel screw .

10. Install the fuel injection pump to the cylinder

block. Refer to Disassembly and Assembly, “Fuel

Injection Pump - Remove and Install” for the

correct procedure.

11. Start the engine and allow the engine to reach

normal operating temperature.

12. Run the engine at low idle speed. Use the

electronic service tool to check if the engine rpm is

the same as “Speed B” .

13. Run the engine at high idle speed. Use the

electronic service tool to check if the engine rpm is

the same as “Speed A” .

Note: The recorded “Speed A” will be higher than

the recorded “Speed B” .

Note: If “Speed A” does not match the high idle

speed or “Speed B” does not match the low idle

speed, contact Global Technical Support.

14. Ensure correct operation of the engine.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

59

Air Inlet and Exhaust System

Air Inlet and Exhaust

System

5. If the breather tube is made of plastic, use low

pressure air to check for a blockage in the breather

tube. If a blockage is inside of the connector, the

cover assembly must be replaced. A broken valve

mechanism cover will result if you try to remove the

connection.

i02251899

i05223369

Air Inlet and Exhaust System -

Inspect

Diesel Particulate Filter - Clean

A general visual inspection should be made to the air

inlet and exhaust system. Make sure that there are no

signs of leaks in the system.

Wear goggles, gloves, protective clothing, and a

National Institute for Occupational Safety and

Health (NIOSH) approved P95 or N95 half-face res-

pirator when handling a used Diesel Particulate

Filter or Catalytic Converter Muffler. Failure to do

so could result in personal injury.

There will be a reduction in the performance of the

engine if there is a restriction in the air inlet system or

the exhaust system.

Hot engine components can cause injury from

burns. Before performing maintenance on the en-

gine, allow the engine and the components to

cool.

The muffler, catalytic converter/muffler, and diesel

particulate filter will become extremely hot during

engine operation. A hot muffler, catalytic convert-

er/muffler and diesel particulate filter can cause

serious burns. Allow adequate cooling time be-

fore working on or near the muffler, catalytic con-

verter/muffler and diesel particulate filter.

Making contact with a running engine can cause

burns from hot parts and can cause injury from

rotating parts.

Diesel Particulate Filters (DPF) require periodic

removal of ash that accumulates from engine oil.

When working on an engine that is running, avoid

contact with hot parts and rotating parts.

Cleaning Procedure

Follow this cleaning procedure for removal of the ash

from a DPF. Refer to Operation and Maintenance

Manual for the intervals of service hours for cleaning

of the DPF.

1. Inspect the engine air cleaner inlet and ducting in

order to ensure that the passageway is not blocked

or collapsed.

2. Inspect the engine air cleaner element. Replace a

dirty engine air cleaner element with a clean

engine air cleaner element.

1. Connect the engine to the electronic service tool

before the DPF is removed from the engine. Once

the engine is connected to the electronic service

tool, then perform an ash service test. This test is a

manual regeneration. The test could take an hour.

3. Check for dirt tracks on the clean side of the engine

air cleaner element. If dirt tracks are observed,

contaminants are flowing past the engine air

cleaner element and/or the seal for the engine air

cleaner element.

Note: Allow the DPF to cool until the DPF can be

safely removed.

2. Remove the DPF from the Clean Emissions

Module (CEM). Refer to Disassembly and

Assembly for the correct procedure.

4. For engines with plastic valve mechanism covers, if

you experience excessive crankcase pressure,

remove the valve mechanism cover and check the

end of the shroud for a skin of plastic. If the end of

the shroud has a skin of plastic, remove the skin of

plastic. Ensure that all of the debris is removed.

Note: Identify all engine fault codes if black soot is

discovered on the outlet side of the center section on

the DPF. Refer to Troubleshooting for problem

identification and the disposition of the DPF.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

60

KENR9144

Air Inlet and Exhaust System

3. The DPF must be cleaned. Contact your nearest

Perkins distributor for assistance.

When the boost pressure increases against the

diaphragm in the canister, the wastegate will open.

The rpm of the turbocharger becomes limited. The

rpm is limited because a portion of the exhaust gases

bypass the turbine wheel of the turbocharger.

4. Reinstall the DPF onto the Clean Emissions

Module (CEM). Refer to Disassembly and

Assembly for the correct procedure.

The following levels of boost pressure indicate a

problem with the wastegate:

Reset the Engine Ash Model

• Too high in full load conditions

The engine ash model must be reset whenever the

filter is cleaned or replaced. Reseting the ash model

places the DPF volume back to the “Clean State” .

The resetting will allow the regeneration of the DPF to

function properly.

• Too low in all low boost conditions

The boost pressure controls the maximum rpm of the

turbocharger, because the boost pressure controls

the position of the wastegate. The following factors

also affect the maximum rpm of the turbocharger:

1. Use the electronic service tool to access the

configuration parameters. Select “Service” from

the top menu and highlight the “DPF Soot Load

Reset” from the menu in the service tool. The

select the “Reset” option.

• The engine rating

• The horsepower demand on the engine

• The high idle rpm

2. The electronic service tool will display “Reset was

Successful” when the calibration has been

completed.

• Inlet air restriction

• Exhaust system restriction

i03011728

Test the Wastegate for Proper Operation

Wastegate - Test

Table 4

Tools Needed

Part Name

Part

Number

Qty

21825617

Dial Gauge

1

Hot engine components can cause injury from

burns. Before performing maintenance on the en-

gine, allow the engine and the components to

cool.

1. Remove the heat shield from the turbocharger.

Remove the guard for the wastegate.

2. Remove the boost line from the wastegate.

Connect an air supply to the wastegate that can be

adjusted accurately.

Note: The turbocharger is a nonserviceable item. The

pressure for the wastegate can be checked but not

adjusted.

3. Fasten a dial gauge to the turbocharger so that the

end of the actuator rod is in contact with the

plunger of the dial gauge. This will measure axial

movement of the actuator rod.

Before the wastegate is tested, be sure that the inlet

air restriction is within the specifications for your

engine. Be sure that the exhaust system restriction is

within the specifications for your engine. Refer to

Testing and Adjusting, “Air Inlet and Exhaust System -

Inspect”.

4. Slowly apply air pressure to the wastegate so that

the actuator rod moves 1.0 mm (0.039 inch). The

air pressure should be within 52 kPa (7.5 psi).

Ensure that the dial gauge returns to zero when

the air pressure is released. Repeat the test

several times. This will ensure that an accurate

reading is obtained.

Inspection of the Wastegate

The wastegate controls the amount of exhaust gas

that is allowed to bypass the turbine side of the

turbocharger. This valve then controls the rpm of the

turbocharger.

When the engine operates in conditions of low boost,

a spring presses against a diaphragm in the canister.

The actuating rod will move and the wastegate will

close. Then, the turbocharger can operate at

maximum performance.

5. Consult your nearest approved Perkins dealer or

your nearest approved Perkins distributor if the

operation of the wastegate is not correct.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9144

61

Air Inlet and Exhaust System

i05191124

g.

Observe the exhaust gas cooler (NRS) for air

bubbles that indicate a leak. If air bubbles are

seen within 30 seconds, this indicates a leak

with the exhaust gas cooler (NRS). Note the

location or the origin of the leak. Record this

information.

Exhaust Cooler (NRS) - Test

(If Equipped)

Air Under Water Leak Test Procedure.

h.

i.

If no bubbles are detected after 30 seconds,

the exhaust gas cooler (NRS) is reusable.

Remove the exhaust gas cooler (NRS) from

the water. If the exhaust gas cooler (NRS)

does not leak, the problem may be elsewhere

in the cooling system or the engine. Refer the

service manual in order to check for leakage. If

the exhaust gas cooler (NRS) does leak, the

exhaust gas cooler (NRS) should be replaced.

2. Follow steps 2.a. to 2.i. in order to test the gas side

of the exhaust gas cooler (NRS).

a.

b.

c.

Plug the gas inlet (5) of the exhaust gas cooler

(NRS) (2).

Plug the gas outlet port (1) with tube and

pressure regulator assembly.

Make sure that the air pressure regulator is

closed and connect compressed air to the

pressure regulator.

Illustration 67

g03326632

Typical example

1. Follow steps 1.a. to 1.i. in order to test the coolant

side of the exhaust gas cooler (NRS).

d.

e.

Use a suitable pressure gauge in order to

apply an air pressure of 300 kPa (44 psi) to

the exhaust gas cooler (NRS).

a.

b.

c.

Plug the coolant inlet (3) of the exhaust gas

cooler (NRS) (2).

While the exhaust gas cooler (NRS) is still

pressurized, submerge the cooler in water that

is at ambient temperature.

Plug the coolant outlet port (4) with tube and

pressure regulator assembly.

f.

Allow the exhaust gas cooler (NRS) to settle in

order for the air that is trapped to escape.

Make sure that the air pressure regulator is

closed and connect compressed air to the

pressure regulator.

g.

Observe the exhaust gas cooler (NRS) for air

bubbles that indicate a leak. If air bubbles are

seen within 30 seconds, this indicates a leak

with the exhaust gas cooler (NRS). Note the

location or the origin of the leak. Record this

information.

d.

e.

f.

Use a suitable pressure gauge in order to

apply an air pressure of 300 kPa (44 psi) to

the exhaust gas cooler (NRS).

While the exhaust gas cooler (NRS) is still

pressurized, submerge the cooler in water that

is at ambient temperature.

h.

i.

If no bubbles are detected after 30 seconds,

the exhaust gas cooler (NRS) is reusable.

Allow the exhaust gas cooler (NRS) to settle in

order for the air that is trapped to escape.

Remove the exhaust gas cooler (NRS) from

the water. If the exhaust gas cooler (NRS)

does not leak, the problem may be elsewhere

in the cooling system or the engine. Refer the

service manual in order to check for leakage. If

the exhaust gas cooler (NRS) does leak, the

exhaust gas cooler (NRS) should be replaced.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

62

KENR9144

Air Inlet and Exhaust System

i02184786

Note: The cylinder compression test should not be

the only test for determining the condition of an

engine.

Compression - Test

Table 5

Standard at

Assembly

Repair Limit

Compression

Compression Pres-

2940 kPa (426 psi) 2450 kPa (355 psi)

The following conditions can affect the results of the

cylinder compression test:

sure(1)

(1)

The compression pressure is taken at 250 rpm.

• The battery is in good condition.

• The battery is fully charged.

6. Repair procedures must be taken if the

compression is lower than the repair limit.

• The starter motor operates correctly.

• The valve lash is set correctly.

• The compression gauge is accurate.

NOTICE

Be sure to measure the compression on all of the cyl-

inders. If all of the cylinders are not checked an im-

proper diagnosis may result. The compression

pressure will vary with the change in engine rpm. It is

necessary to keep the engine rpm constant for all cyl-

inders when you are taking a compression reading.

i04904667

Engine Valve Lash - Inspect/

Adjust

To prevent possible injury, do not use the starter

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before meas-

uring valve clearance.

Illustration 68

g00564993

Valve Lash Setting

The valve lash setting is for a cold engine.

Valve lash setting

Checking compression of the engine

1. Remove the fuel injector from the cylinder in order

to measure the compression for that cylinder.

2. Connect a suitable compression gauge to the

cylinder.

Inlet valve.... 0.2 ± 0.05 mm (0.008 ± 0.0020 inch)

Exhaust valve.................................0.2 ± 0.05 mm

(0.008 ± 0.0020 inch)

3. Disconnect the fuel shutoff solenoid.

Valve Lash Adjustment

4. Operate the starter motor and record the pressure

on the compression gauge.

If the valve lash requires adjustment several times in

a short time period, excessive wear exists in a

different part of the engine. Repair the problem in

order to prevent more damage to the engine.

5. Repeat for each cylinder.

Note: Compression tests should only be used to

compare pressures between cylinders of an engine. If

one or more cylinders vary more than 350 kPa

(51 psi) then those cylinders may be damaged.

Not enough valve lash can be the cause of rapid wear

of the camshaft and valve lifters. Not enough valve

lash can indicate that the seats for the valves are

worn.

Valves become worn due to the following causes:

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

63

Air Inlet and Exhaust System

• Incorrect operation of fuel injectors

• Excessive dirt and oil are present on the filters for

the inlet air.

Accidental engine starting can cause injury or

death to personnel.

• Incorrect fuel settings on the fuel injection pump.

To prevent accidental engine starting, turn the

ignition switch to the OFF position and place a do

not operate tag at the ignition switch location.

• The load capacity of the engine is frequently

exceeded.

Too much valve lash can cause broken valve stems,

springs, and spring retainers. Too much valve lash

can be an indication of the following problems:

Valve Lash Adjustment for Three Cylinder

Engines

• Worn camshaft and valve lifters

• Worn rocker arms

NOTICE

Ensure that this valve lash adjustment procedure is

followed for the three cylinder engine. Do not use the

traditional opposing cylinders method. Failure to fol-

low the correct procedure may result in serious en-

gine damage.

• Bent pushrods

• Broken socket on the upper end of a pushrod

• Loose adjustment screw for the valve lash

If the camshaft and valve lifters show rapid wear, look

for fuel in the lubrication oil or dirty lubrication oil as a

possible cause.

Firing order for the three cylinder engine ...........1, 2, 3

The valve lash is measured between the top of the

valve stem and the rocker arm lever.

Note: No. 1 cylinder is at the front of the engine.

Remove the valve mechanism cover and perform the

following procedures in order to adjust the valve lash:

Note: When these procedures are performed, the

front housing must be installed.

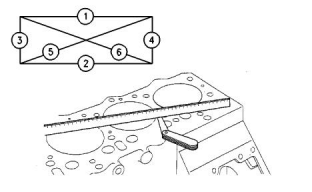

Illustration 69

g01107989

Setting the valve lash

Illustration 70

g03340757

(1) Feeler gauge

(2) Adjustment screw

A typical example of the crankshaft pulley and front

housing

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

64

KENR9144

Air Inlet and Exhaust System

If adjustment is necessary, refer to steps 2.a., 2.b.,

and 2.c..

4. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. Rotate the

crankshaft clockwise until the piston of No. 3

cylinder is at the top center position on the

compression stroke. Ensure that the “Top” mark

(3) on the timing case aligns with “Dot” (6) on the

crankshaft pulley. Check the valve lash of the inlet

valve for No. 3 cylinder and the exhaust valve for

No. 3 cylinder.

If adjustment is necessary, refer to steps 2.a., 2.b.,

and 2.c..

Valve Lash Adjustment for Four Cylinder

Engines

Illustration 71

g03340758

Top center markings for the Crankshaft pulley

1. Rotate the crankshaft clockwise until the piston of

No. 1 cylinder is at the top center position on the

compression stroke. Refer to Systems Operation,

Testing and Adjusting, “Finding Top Center

Position for No. 1 Piston” for the correct procedure.

Ensure that the “Top” mark (3) on the timing case

aligns with “Dot” (4) on the crankshaft pulley.

2. Check the valve lash of the inlet valve of No. 1

cylinder and the exhaust valve of No. 1 cylinder. If

necessary, make adjustment.

a.

Loosen the valve adjustment screw locknut

that is on adjustment screw (2).

b.

Place the appropriate feeler gauge (1)

between the rocker arm and the valve. Turn

adjustment screw (2) while the valve

adjustment screw locknut is being held from

turning. Adjust the valve lash until the correct

specification is achieved.

Illustration 72

g03340755

A typical example of the crankshaft pulley and front

housing

c.

After each adjustment, tighten the valve

adjustment screw locknut while adjustment

screw (2) is being held from turning.

3. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. Rotate the

crankshaft clockwise until the piston of No. 2

cylinder is at the top center position on the

compression stroke. Ensure that the “Top” mark

(3) on the timing case aligns with “Dot” (5) on the

crankshaft pulley. Check the valve lash of the inlet

valve for No. 2 cylinder and the exhaust valve for

No. 2 cylinder.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

65

Air Inlet and Exhaust System

2. Rotate the crankshaft in a clockwise direction 360°.

When the inlet valve of the No. 1 cylinder has

started to open and the exhaust valve of the No. 1

cylinder has not closed, ensure that the “Top”

mark (3) on the timing case aligns with “Single

dot” (4) on the crankshaft pulley. Check the valve

lash of the exhaust valve of the No. 2 cylinder.

Check the valve lash of the inlet valve of the No. 3

cylinder. Check the valve lash of the inlet valve and

the exhaust valve of the No. 4 cylinder. If

necessary, make an adjustment.

If adjustment is necessary, refer to Steps 1.a., 1.b.,

and 1.c. above.

i02193792

Valve Depth - Inspect

Table 6

Illustration 73

g03340756

Top center markings for the Crankshaft pulley

Required Tools

Part Number

21825617

21825496

Part Description

Dial gauge

Qty

1

1. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. When the

inlet valve of the No. 4 cylinder has started to open

and the exhaust valve of the No. 4 cylinder has not

closed, ensure that the “Top” mark (3) on the

timing case aligns with “Single dot” (4) on the

crankshaft pulley. Check the valve lash of the inlet

valve and the exhaust valve of the No. 1 cylinder.

Check the valve lash of the inlet valve of the No. 2

cylinder. Check the valve lash of the exhaust valve

of the No. 3 cylinder. If necessary, make an

adjustment.

Dial gauge holder

1

Note: The “Single dot” (4) on the crankshaft pulley is

the reference point for the top center position of No. 1

cylinder.

a.

Loosen the valve adjustment screw locknut

that is on adjustment screw (2).

b.

Place the appropriate feeler gauge (1)

between the rocker arm and the valve. Turn

adjustment screw (2) while the valve

adjustment screw locknut is being held from

turning. Adjust the valve lash until the correct

specification is achieved.

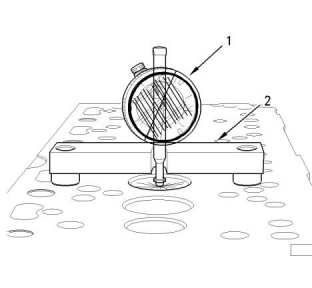

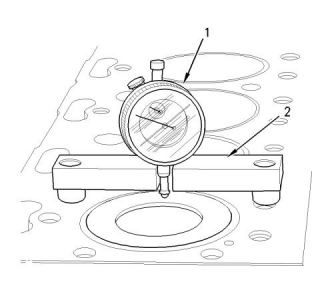

Illustration 74

g00953530

(1) Dial gauge

(2) Dial gauge holder

c.

After each adjustment, tighten the valve

adjustment screw locknut while adjustment

screw (2) is being held from turning.

1. Use the dial gauge (1) with the dial gauge holder

(2) to check the depths of the inlet valves and the

exhaust valves below the face of the cylinder head.

Use the cylinder head face (3) to zero the dial

gauge (1).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

66

KENR9144

Air Inlet and Exhaust System

2. Position the dial gauge holder (2) and the dial

gauge (1) in order to measure the valve depth.

Measure the depth of the inlet valve and the

exhaust valve before the valve springs are

removed.

4. Move the valve in a radial direction away from the

dial indicator. Make sure that the valve moves

away from the dial indicator as far as possible.

Position the contact point of the dial indicator on

the edge of the valve head. Set the position of the

needle of the dial indicator to zero.

Refer to Specifications, “Cylinder Head Valves” for

the minimum, the maximum, and the service wear

limits for the valve depth below the cylinder head

face.

5. Move the valve in a radial direction toward the dial

indicator as far as possible. Note the distance of

movement which is indicated on the dial indicator.

If the distance is greater than the maximum

clearance of the valve in the valve guide, replace

the valve guide. Refer to Specifications, “Cylinder

Head Valves” for the maximum clearance of the

valve in the valve guide.

If the valve depth below the cylinder head face

exceeds the service limit, use a new valve to check

the valve depth. If the valve depth still exceeds the

service limit, renew the cylinder head or renew the

valve seat inserts (if equipped). If the valve depth

is within the service limit, renew the valves.

3. Inspect the valves for cracks and other damage.

Check the valve stems for wear. Check that the

valve springs are the correct length under the test

force. Refer to Specifications, “Cylinder Head

Valves” for the dimensions and tolerances of the

valves and valve springs.

i01962876

Valve Guide - Inspect

Perform this test in order to determine if a valve guide

should be replaced.

Illustration 75

g00314806

(1) Valve guide

(2) Radial movement of the valve in the valve guide

(3) Valve stem

(4) Dial indicator

(5) Valve head

1. Place a new valve in the valve guide.

2. Place the dial indicator with the magnetic base on

the face of the cylinder head.

3. Lift the edge of the valve head to a distance of

15.0 mm (0.60 inch).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9144

67

Lubrication System

LubricationSystem

Perform the following procedures in order to inspect

the engine oil pump. Refer to Specifications, “Engine

Oil Pump”.

i02193793

Engine Oil Pressure - Test

An oil pressure gauge that has a defect can indicate

low oil pressure.

Use a suitable gauge that measures the oil pressure

in the engine.

1. Ensure that the engine is filled to the correct oil

level.

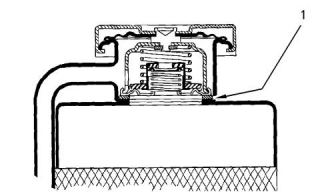

Illustration 76

g00458938

2. Connect the gauge to a pressure tap location for

Idler gear and components of the engine oil pump

engine oil.

(1) C-clip

(2) Collar

(3) Spring

3. Operate the engine. Allow the engine to obtain

(4) Shim

normal operating temperature.

(5) Oil pump cover

(6) Inner rotor

(7) Spring

(8) Outer rotor

(9) Bushing

(10) Idler gear

(11) Thrust washer

4. Keep the oil temperature constant with the engine

at the rated rpm. Read the pressure gauge.

5. Refer to Table 7 in order to determine if the engine

oil pressure is in tolerance.

Table 7

1. Remove the front housing. Remove C-clip (1).

Oil Pressure(1)

Note: If the front housing is removed, do not turn the

crankshaft.

196 to 441 kPa

Oil Pressure at high idle

(28.4 to 64 psi)

2. Disassemble the engine oil pump. Refer to

Disassembly and Assembly, “Engine Oil Pump -

Remove” for additional information. Do not remove

bushing (9) from idler gear (10) unless damage is

observed.

Oil Pressure at low idle

49 kPa (7.1 psi) or more

(1)

The oil temperature must be 80° to 110°C (176° to 230°F).

Troubleshoot the cause of the problem and correct

the problem if the results of the test do not fall within

the pressure range in Table 7 . Engine failure or a

reduction in engine life can be the result if engine

operation is continued with oil pressure outside this

range.

3. Clean all of the parts and inspect the parts for

cracks in the metal or other damage. Look for wear

on the components. Ensure that bushing (9) is not

loose in idler gear (10).

Note: A record of engine oil pressure at regular

intervals can be used as an indication of possible

problems of the engine. A record of engine oil

pressure at regular intervals can also be used as an

indication of possible damage to the engine. The

engine should be inspected and the problem should

be corrected if there is a sudden increase or a sudden

decrease of 70 kPa (10 psi) in oil pressure.

i02617860

Engine Oil Pump - Inspect

If any part of the engine oil pump is worn enough in

order to affect the performance of the engine oil

pump, the engine oil pump must be replaced.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

68

KENR9144

Lubrication System

The distance between the faces is adjusted with

shims (4). The thicknesses of the shims are given

in Specifications, “Engine Oil Pump”.

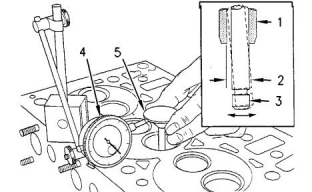

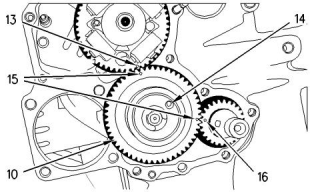

Illustration 79

g00826185

7. Install the components of the engine oil pump and

the front housing on the cylinder block. Make sure

that the two dowels align with the bushing, the

outer rotor, and the holes in the idler gear.

Illustration 77

g00459701

Clearance between the inner rotor and the outer rotor

4. Install the idler gear and the inner rotor on the

shaft. Measure clearance (A) between inner rotor

(6) and outer rotor (8).

Align the timing mark (15) on idler gear (10) with

the timing mark on crankshaft gear (16) when you

install the idler gear on the oil pump shaft. Also,

align the other timing mark (15) on idler gear (10)

with the timing mark on the camshaft gear (13).

The hole (14) in oil pump cover (5) should align

with the locating pin in the front housing.

Refer to Specifications, “Engine Oil Pump”.

Note: When the front housing is not installed on the

engine, do not rotate the crankshaft.

i01126690

Excessive Bearing Wear -

Inspect

When some components of the engine show bearing

wear in a short time, the cause can be a restriction in

an oil passage.

Illustration 78

g01290817

Face of the cover for the oil pump above the face of

the idler gear

An engine oil pressure indicator may show that there

is enough oil pressure, but a component is worn due

to a lack of lubrication. In such a case, look at the

passage for the oil supply to the component. A

restriction in an oil supply passage will not allow

enough lubrication to reach a component. This will

result in early wear.

(1) C-clip

(2) Collar

(4) Shim

(12) Feeler gauge

5. Use feeler gauge (12) to measure the distance

between C-clip (1) and collar (2).

6. When the components of the engine oil pump are

installed on the front housing, measurement (B)

between C-clip (1) and collar (2) must be between

0.10 to 0.15 mm (0.004 to 0.006 inch)for new

components. Dimension B must be not more than

0.20 mm (0.008 inch) for used parts.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

69

Lubrication System

i03993149

Excessive Engine Oil

Consumption - Inspect

Engine Oil Leaks on the Outside of

the Engine

Check for leakage at the seals at each end of the

crankshaft. Look for leakage at the gasket for the

engine oil pan and all lubrication system connections.

Look for any engine oil that may be leaking from the

crankcase breather. This can be caused by

combustion gas leakage around the pistons. A dirty

crankcase breather will cause high pressure in the

crankcase. A dirty crankcase breather will cause the

gaskets and the seals to leak.

Engine Oil Leaks into the

Combustion Area of the Cylinders

Engine oil that is leaking into the combustion area of

the cylinders can be the cause of blue smoke. There

are several possible ways for engine oil to leak into

the combustion area of the cylinders:

• Leaks between worn valve guides and valve stems

• Worn components or damaged components

(pistons, piston rings, or dirty return holes for the

engine oil)

• Incorrect installation of the compression ring and/

or the intermediate ring

• Leaks past the seal rings in the turbocharger shaft

• Overfilling of the crankcase

• Wrong oil level gauge or guide tube

• Sustained operation at light loads

Excessive consumption of engine oil can also result if

engine oil with the wrong viscosity is used. Engine oil

with a thin viscosity can be caused by increased

engine temperature.

This document is printed from SPI². Not for RESALE

![]()

70

KENR9144

Cooling System

Cooling System

b.

Check for debris or damage between the fins

of the radiator core. Debris between the fins of

the radiator core restricts air flow through the

radiator core. Refer to Testing and Adjusting,

“Cooling System - Inspect”.

i02193795

Cooling System - Check

(Overheating)

6. Check the filler cap. A pressure drop in the cooling

system can cause the boiling point to be lower.

This can cause the cooling system to boil. Refer to

Testing and Adjusting, “Cooling System - Test”.

Above normal coolant temperatures can be caused

by many conditions. Use the following procedure to

determine the cause of above normal coolant

temperatures:

7. Check the fan and/or the fan shroud. The fan

shroud must be the proper size and the fan shroud

must be positioned correctly.

1. Check the coolant level in the cooling system. If the

coolant level is too low, air will get into the cooling

system. Air in the cooling system will cause a

reduction in coolant flow and bubbles in the

coolant. Air bubbles will keep the coolant away

from the engine parts, which will prevent the

transfer of heat to the coolant. Low coolant level is

caused by leaks or incorrectly filling the expansion

tank.

8. Check for loose drive belts.

a.

A loose fan drive belt will cause a reduction in

the air flow across the radiator. Check the fan

drive belt for proper belt tension. Adjust the

tension of the fan drive belt, if necessary. Refer

to the Testing and Adjusting Section, “Belt

Tension Chart”.

b.

A loose water pump drive belt will cause a

reduction in coolant flow through the radiator.

Check the water pump drive belt for proper belt

tension. Adjust the water pump drive belt's

tension, if necessary. Refer to the Testing and

Adjusting Section, “Belt Tension Chart”.

2. If contamination of the coolant is suspected, refer

to Operation and Maintenance, “Maintenance

Section”for the correct specification of coolant.

3. Check for air in the cooling system. Air can enter

the cooling system in different ways. The most

common causes of air in the cooling system are

not filling the cooling system correctly and

combustion gas leakage into the cooling system.

Combustion gas can get into the system through

inside cracks, a damaged cylinder head, or a

damaged cylinder head gasket. Air in the cooling

system causes a reduction in coolant flow and

bubbles in the coolant. Air bubbles keep the

coolant away from the engine parts, which

prevents the transfer of heat to the coolant.

9. Check the cooling system hoses and clamps.

Damaged hoses with leaks can normally be seen.

Hoses that have no visual leaks can soften during

operation. The soft areas of the hose can become

kinked or crushed during operation. These areas of

the hose can cause a restriction in the coolant flow.

Hoses become soft and/or get cracks after a

period of time. The inside of a hose can

deteriorate, and the loose particles of the hose can

cause a restriction of the coolant flow.

10. Check for a restriction in the air inlet system. A

restriction of the air that is coming into the engine

can cause high cylinder temperatures. High

cylinder temperatures require higher than normal

temperatures in the cooling system.

4. Check the sending unit. In some conditions, the

temperature sensor in the engine sends signals to

a sending unit. The sending unit converts these

signals to an electrical impulse which is used by a

mounted gauge. If the sending unit malfunctions,

the gauge can show an incorrect reading. Also if

the electric wire breaks or if the electric wire shorts

out, the gauge can show an incorrect reading.

11. Check for a restriction in the exhaust system. A

restriction of the air that is coming out of the engine

can cause high cylinder temperatures.

5. Check the radiator.

a.

Make a visual inspection of the exhaust

system.

a.

Check the radiator for a restriction to coolant

flow. Check the radiator for debris, dirt, or

deposits on the inside of the core. Debris, dirt,

or deposits will restrict the flow of coolant

through the radiator.

b.

Check for damage to exhaust piping. Check

for damage to the exhaust elbow. If no damage

is found, check the exhaust system for a

restriction.

This document is printed from SPI². Not for RESALE

![]()

KENR9144

71

Cooling System

12. Check the water temperature regulator. A water

temperature regulator that does not open, or a

water temperature regulator that only opens part of

the way can cause overheating. Refer to Testing

and Adjusting, “Water Temperature Regulator -

Test”.

Note: A small amount of coolant leakage across the

surface of the water pump seals is normal. This

leakage is required in order to provide lubrication for

this type of seal. A hole is provided in the water pump

housing in order to allow this coolant/seal lubricant to

drain from the pump housing. Intermittent leakage of

small amounts of coolant from this hole is not an

indication of water pump seal failure.

13. Check the water pump. A water pump with a

damaged impeller does not pump enough coolant

for correct engine cooling. Remove the water

pump and check for damage to the impeller.

3. Make sure that air flow through the radiator does

not have a restriction. Look for bent core fins

between the folded cores of the radiator. Also, look

for debris between the folded cores of the radiator.

14. Consider high outside temperatures. When

outside temperatures are too high for the rating of

the cooling system, there is not enough of a

temperature difference between the outside air and

coolant temperatures. The maximum temperature

of the ambient air that enters the engine should not

exceed 50 °C (120 °F).

4. Inspect the drive belts for the fan.

5. Check for damage to the fan blades.

6. Look for air or combustion gas in the cooling

system.

15. When a load that is applied to the engine is too

large, the engine rpm does not increase with an

increase of fuel. This lower engine rpm causes a

reduction in coolant flow through the system. This

combination of less air and less coolant flow during

high input of fuel will cause above normal heating.

7. Inspect the filler cap, and check the surface that

seals the filler cap. This surface must be clean.

8. Look for large amounts of dirt in the radiator core.

Look for large amounts of dirt on the engine.

Remove the dirt from the radiator core and the

engine.

16. Timing of the engine which is incorrect may also

cause overheating of the engine. Late timing

creates more heat in the engine. Early timing

creates less heat in the engine.

9. Fan shrouds that are loose or missing cause poor

air flow for cooling.

i01964006

Note: If the timing of the engine is incorrect, the

exhaust valves may be burned and damage to the

exhaust manifold may occur.

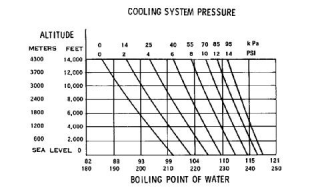

Cooling System - Test

Remember that temperature and pressure work

together. When a diagnosis is made of a cooling

system problem, temperature and pressure must be

checked. The cooling system pressure will have an

effect on the cooling system temperature. For an

example, refer to Illustration 80 . This will show the

effect of pressure on the boiling point (steam) of

water. This will also show the effect of height above

sea level.

i01300404

Cooling System - Inspect

Cooling systems that are not regularly inspected are

the cause for increased engine temperatures. Make a

visual inspection of the cooling system before any

tests are performed.

Personal injury can result from escaping fluid

under pressure.

If a pressure indication is shown on the indicator,

push the release valve in order to relieve pressure

before removing any hose from the radiator.

1. Check the coolant level in the cooling system.

2. Look for leaks in the system.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

72

KENR9144

Cooling System

Illustration 80

g00286266

Illustration 81

g00296067

Cooling system pressure at specific altitudes and

boiling points of water

Typical schematic of filler cap

(1) Sealing surface between the pressure cap and the radiator

Personal injury can result from hot coolant, steam

and alkali.

Personal injury can result from hot coolant, steam

and alkali.

At operating temperature, engine coolant is hot

and under pressure. The radiator and all lines to

heaters or the engine contain hot coolant or

steam. Any contact can cause severe burns.

At operating temperature, engine coolant is hot

and under pressure. The radiator and all lines to

heaters or the engine contain hot coolant or

steam. Any contact can cause severe burns.

Remove filler cap slowly to relieve pressure only

when engine is stopped and radiator cap is cool

enough to touch with your bare hand.

Remove filler cap slowly to relieve pressure only

when engine is stopped and radiator cap is cool

enough to touch with your bare hand.

The coolant level must be to the correct level in order

to check the coolant system. The engine must be cold

and the engine must not be running.

To check for the amount of pressure that opens the

filler cap, use the following procedure:

1. After the engine cools, carefully loosen the filler

cap. Slowly release the pressure from the cooling

system. Then, remove the filler cap.

After the engine is cool, loosen the pressure cap in

order to relieve the pressure out of the cooling

system. Then remove the pressure cap.

The level of the coolant should not be more than

13 mm (0.5 inch) from the bottom of the filler pipe. If

the cooling system is equipped with a sight glass, the

coolant should be to the correct level in the sight

glass.

2. Inspect the pressure cap carefully. Look for

damage to the seal. Look for damage to the

surface that seals. Remove any debris on the cap,

the seal, or the sealing surface.

Carefully inspect the filler cap. Look for any

damage to the seals and to the sealing surface.

Inspect the following components for any foreign

substances:

Checking the Filler Cap

One cause for a pressure loss in the cooling system

can be a faulty seal on the radiator pressure cap.

• Filler cap

• Seal

• Surface for seal

Remove any deposits that are found on these

items, and remove any material that is found on

these items.

3. Install the pressure cap onto a suitable

pressurizing Pump.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

73

Cooling System

4. Observe the exact pressure that opens the filler

i05183360

cap.

Water Temperature Regulator -

Test

5. Compare the pressure to the pressure rating that is

found on the top of the filler cap.

6. If the filler cap is damaged, replace the filler cap.

Introduction

Testing The Radiator And Cooling

System For Leaks

This procedure is intended to give information on

testing the water temperature regulator.

Use the following procedure to test the radiator and

the cooling system for leaks.

Test Procedure

Personal injury can result from escaping fluid

under pressure.

Personal injury can result from hot coolant, steam

and alkali.

If a pressure indication is shown on the indicator,

push the release valve in order to relieve pressure

before removing any hose from the radiator.

At operating temperature, engine coolant is hot

and under pressure. The radiator and all lines to

heaters or the engine contain hot coolant or

steam. Any contact can cause severe burns.

1. Remove the water temperature regulator from the

engine.

Remove filler cap slowly to relieve pressure only

when engine is stopped and radiator cap is cool

enough to touch with your bare hand.

2. Heat water in a pan until the temperature of the

water is equal to the fully open temperature of the

water temperature regulator. Refer to

Specifications, “Water Temperature Regulator” for

the fully open temperature of the water

temperature regulator. Stir the water in the pan.

This will distribute the temperature throughout the

pan.

1. When the engine has cooled, loosen the filler cap

to the first stop. Allow the pressure to release from

the cooling system. Then remove the filler cap.

2. Make sure that the coolant covers the top of the

radiator core.

3. Put a suitable pressurizing Pump onto the radiator.

3. Hang the water temperature regulator in the pan of

water. The water temperature regulator must be

below the surface of the water. The water

temperature regulator must be away from the sides

and the bottom of the pan.

4. Use the pressurizing pump to increase the

pressure to an amount of 20 kPa (3 psi) more than

the operating pressure of the filler cap.

5. Check the radiator for leakage on the outside.

4. Keep the water at the correct temperature for ten

minutes.

6. Check all connections and hoses of the cooling

system for leaks.

5. After ten minutes, remove the water temperature

regulator. Immediately measure the opening of the

water temperature regulator. Refer to

Specifications, “Water Temperature Regulator” for

the minimum opening distance of the water

temperature regulator at the fully open

temperature.

The radiator and the cooling system do not have

leakage if all of the following conditions exist:

• You do NOTobserve any leakage after five

minutes.

• The dial indicator remains constant beyond five

minutes.

If the distance is less than the amount listed in the

manual, replace the water temperature regulator.

The inside of the cooling system has leakage only

if the following conditions exist:

i02193835

• The reading on the gauge goes down.

Water Pump - Inspect

• You do NOTobserve any outside leakage.

Make any repairs, as required.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

74

KENR9144

Cooling System

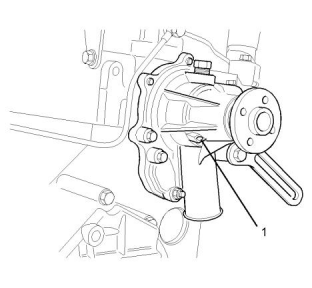

Illustration 82

g01109205

1. Start the engine. Inspect the water pump for

excessive leaks at the vent hole (1).

Note: A small amount of coolant leakage across the

surface of the seal for the jacket water pump is

normal. This leakage is required to provide lubrication

for this type of seal. A hole is provided in the water

pump housing in order to allow this coolant/seal

lubricant to drain from the water pump housing.

Intermittent leakage of small amounts of coolant from

this hole is not an indication of water pump seal

failure.

2. Inspect the water pump shaft for unusual noise,

excessive looseness and/or vibration of the

bearings.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9144

75

Basic Engine

Basic Engine

i02965792

Piston Ring Groove - Inspect

Inspect the Piston and the Piston

Rings

1. Check the piston for wear and other damage.

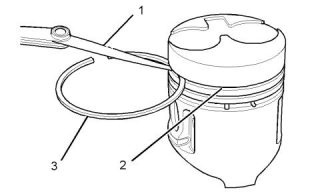

Illustration 84

g01109214

2. Check that the piston rings are free to move in the

grooves and that the rings are not broken.

(1) Feeler gauge

(2) Piston ring

Inspect the Clearance of the Piston

Ring

1. Clean all carbon from the top of the cylinder bores.

2. Place each piston ring (2) in the cylinder bore.

1. Remove the piston rings and clean the grooves

and the piston rings.

3. Use a suitable feeler gauge (1) to measure piston

ring end gap. Refer to Specifications, “Piston and

Rings” for the dimensions.

Note: The coil spring must be removed from the oil

control ring before the gap of the oil control ring is

measured.

i02193842

Connecting Rod - Inspect

This procedure determines the following

characteristics of the connecting rod:

• The distortion of the connecting rod

Illustration 83

g01109213

• The parallel alignment of the bores of the

connecting rod

(1) Feeler gauge

(2) Piston grooves

(3) Piston ring

2. Fit new piston rings (3) in the piston grooves (2).

3. Check the clearance for the piston ring by placing a

suitable feeler gauge (1) between piston groove (2)

and the top of piston ring (3). Refer to

Specifications, “Piston and Rings” for the

dimensions.

Note: On 403D-15T, 404D-22Tand 404D-22TA

engines, the pistons have a tapered top groove and

the piston ring is wedged. The clearance for the top

piston ring cannot be checked by the above method

when this occurs.

Inspect the Piston Ring End Gap

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

76

KENR9144

Basic Engine

Connecting rod bearings are available with a smaller

inside diameter than the original size bearings. These

bearings are for crankshafts that have been ground.

i01748792

Main Bearings - Inspect

Check the main bearings for wear or other damage.

Replace both halves of the bearings and check the

condition of the other bearings if a main bearing is

worn or damaged.

Main bearings are available with a smaller inside

diameter than the original size bearings. These

bearings are for main bearing journals that have been

ground.

Illustration 85

g00690891

Inspection of the connecting rod parallel alignment.

(1) Measuring pins

(2) Connecting rod

(A) Measure the distance 100 mm (3.94 inch) from the connecting

rod.

i02193978

(B) Measure the distance between the center of the bore for the

piston pin bearing and the center of the connecting rod bearing

bore.

Cylinder Block - Inspect

1. Use the appropriate tools in order to measure the

distances for the connecting rod (2).

• Appropriate gauges for measuring distance

• Measuring pins (1)

Note: The connecting rod bearings should be

removed before taking the measurements.

2. Measure the connecting rod for distortion and

parallel alignment between the bores.

The measurements must be taken at distance (A).

Distance (A) has a value of 100 mm (3.94 inch)

from both sides of the connecting rod.

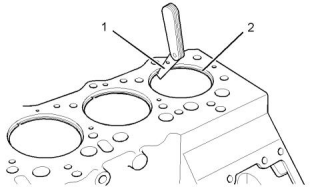

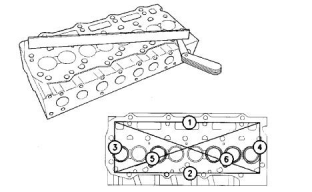

Illustration 86

g00907375

Measure length (B).

Use a straight edge and a feeler gauge to check the

six positions for flatness. Refer to Illustration 86 .

The total difference in measurements of length (B)

from each side should not vary more than

± 0.08 mm (± 0.0031 inch).

Inspect the top of the cylinder block for cracks,

damage, and warpage.

3. Inspect the piston pin bearing and the piston pin for

wear and other damage.

Inspect each cylinder bore. There should be no

scoring, rust or corrosion. Use a suitable gauge in

order to measure each cylinder bore. Measure the

area of each cylinder bore that is in contact with the

top, middle and bottom piston rings. Each cylinder

bore should be measured at 90 degrees to the

crankshaft.

4. Measure the clearance of the piston pin in the

piston pin bearing. Refer to Specifications,

“Connecting Rod” for clearance dimensions.

i01748770

NOTICE

The flex-hone process must not be used on these

engines.

Connecting Rod Bearings -

Inspect

If the cylinder bores exceed the service limit, the

cylinder block must be renewed. Refer to

Specifications, “Cylinder Block” for the bore

diameters and tolerances.

Check the connecting rod bearings and the

connecting rod bearing journal for wear or other

damage.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9144

77

Basic Engine

i04904653

Cylinder Head - Inspect

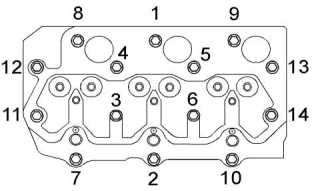

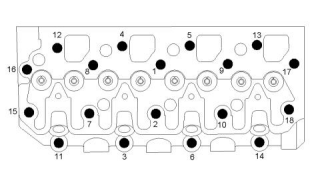

Illustration 87

g01317351

Bolt tightening sequence for the 403F-15T engines

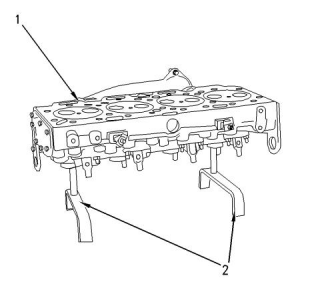

Illustration 89

g00842292

Typical example

4. Put the cylinder head (1) on suitable supports (2).

Illustration 88

g01109567

Bolt tightening sequence for the 404D-22, and 404D-

22T engines

Illustration 90

g00907448

1. Remove the bolts in the cylinder head in the

reverse sequence that is shown in Illustrations 87

and 88 .

Typical example

5. Use a straight edge and a feeler gauge to check

the six positions of the cylinder head for distortion.

Refer to Specifications, “Cylinder Head” for the

requirements of flatness.

Remove the cylinder head from the engine.

2. Clean the cylinder head thoroughly. Ensure that the

contact surface of the cylinder head and the

contact surface of the cylinder block are clean,

smooth, and flat.

i02194219

Piston Height - Inspect

3. Inspect the bottom surface of the cylinder head for

pitting, corrosion, and cracks. Inspect the area

around the valve seats and the holes for the fuel

injectors.

Table 8

Required Tools

Part Number

21825617

21825496

Part Description

Dial gauge

Qty

1

Dial gauge holder

1

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

78

KENR9144

Basic Engine

If the height of the piston above the cylinder block is

not within the tolerance that is given in the

Specifications Module, “Piston and Rings”, the

bearing for the piston pin must be checked. Refer to

Testing and Adjusting, “Connecting Rod - Inspect”. If

any of the following components are replaced or

remachined, the piston height above the cylinder

block must be measured:

3. Position the dial gauge holder (2) and the dial

gauge (1) in order to measure the piston height

above the cylinder block. Slowly rotate the

crankshaft in order to determine when the piston is

at the highest position. Record this dimension.

Compare this dimension with the dimensions that

are given in Specifications, “Cylinder Head”.

• Crankshaft

i02194222

• Cylinder head

Flywheel - Inspect

• Connecting rod

• Bearing for the piston pin

Alignment of the Flywheel Face

The correct piston height must be maintained in order

to ensure that the engine conforms to the standards

for emissions.

Note: The top of the piston must not be machined. If

the original piston is installed, be sure that the original

piston is assembled to the correct connecting rod and

installed in the original cylinder.

Illustration 92

g00987751

1. Install the dial indicator. Refer to Illustration 92 .

2. Set the pointer of the dial indicator to 0 mm

(0 inch).

Illustration 91

g00953648

3. Turn the flywheel. Read the dial indicator for every

(1) Dial gauge

(2) Dial gauge holder

90 degrees.

Note: During the check, keep the crankshaft pressed

toward the front of the engine in order to remove any

end clearance.

1. Use the dial gauge (1) and the dial gauge holder

(2) in order to measure the piston height above the

cylinder block. Use the cylinder block face to zero

the dial gauge (1).

4. Calculate the difference between the lowest

measurement and the highest measurement of the

four locations. This difference must not be greater

than 0.03 mm (0.001 inch) for every 25 mm

(1.0 inch) of the radius of the flywheel. The radius

of the flywheel is measured from the axis of the

crankshaft to the contact point of the dial indicator.

2. Rotate the crankshaft until the piston is at the

approximate top center.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

79

Basic Engine

Flywheel Runout

Face Runout (Axial Eccentricity)of

the Flywheel Housing

Illustration 94

g00285931

21825617 Dial Indicator Group

1. Fasten a dial indicator to the flywheel so the anvil

of the dial indicator will contact the face of the

flywheel housing.

Illustration 93

g00987752

1. Install the dial indicator. Refer to Illustration 93 .

2. Put a force on the crankshaft toward the rear

before the dial indicator is read at each point.

2. Set the pointer of the dial indicator to 0 mm

(0 inch).

3. Turn the flywheel. Read the dial indicator for every

90 degrees.

4. Calculate the difference between the lowest

measurement and the highest measurement of the

four locations. This difference must not be greater

than 0.20 mm (0.008 inch).

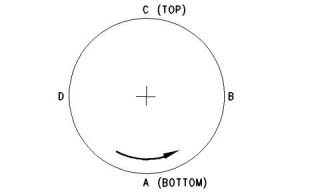

i05191413

Flywheel Housing - Inspect

Illustration 95

g00285932

Table 9

Checking face runout of the flywheel housing

Required Tools

Part

Number

3. Turn the flywheel while the dial indicator is set at

0.0 mm (0.00 inch) at location (A). Read the dial

indicator at locations (B), (C), and (D).

Part Name

Qty

21825617

Dial Indicator Group

1

4. The difference between the lower measurements

and the higher measurements that are performed

at all four points must not be more than 0.20 mm