珀金斯403F-15T、404F-22、404F-22T維修技術參數一(英文)

詳細描述

Specifications

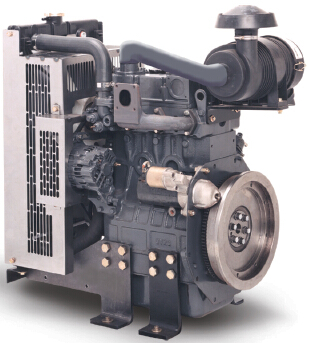

403F-15T, 404F-22 and 404F-22T

Industrial Engines

EL (Engine)

EN (Engine)

EP (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9143

3

Table of Contents

Table of Contents

Glow Plugs .......................... ........................... 33

Index Section

SpecificationsSection

Index................................ ............................... 35

Engine Design ......................... ......................... 4

Fuel Injection Lines...................... ..................... 5

Fuel Injection Pump..................... ..................... 5

Fuel Injector........................... ........................... 6

Fuel Transfer Pump..................... ..................... 6

Lifter Group............................ ........................... 7

Rocker Shaft........................... .......................... 7

Valve Mechanism Cover.................. ................. 8

Cylinder Head Valves .................... ................... 8

Cylinder Head......................... ........................ 10

Turbocharger......................... ......................... 12

Air Pump (ARD Air)..................... .................... 12

Exhaust Cooler (NRS) (If equipped)........ ....... 13

Exhaust Manifold...................... ...................... 14

Exhaust Combustion (ARD) .............. ............. 14

Camshaft............................ ............................ 15

Engine Oil Lines....................... ....................... 17

Engine Oil Relief Valve.................. ................. 17

Engine Oil Pump....................... ...................... 18

Engine Oil Pan........................ ........................ 19

Crankcase Breather.................... .................... 20

Water Temperature Regulator ............ ............ 20

Cylinder Block......................... ........................ 21

Crankshaft........................... ........................... 21

Connecting Rod Bearing Journal.......... .......... 22

Main Bearing Journal................... ................... 23

Connecting Rod....................... ....................... 23

Piston and Rings ...................... ...................... 24

Balancer .......................................................... 25

Housing (Front)........................ ....................... 26

Gear Group (Front)..................... .................... 26

Flywheel .......................................................... 27

Flywheel Housing...................... ..................... 27

Crankshaft Pulley ...................... ..................... 28

Belt Tension Chart ..................... ..................... 29

Fan Drive............................ ............................ 29

Engine Lifting Bracket................... .................. 29

Alternator and Regulator................. ................ 30

Electric Starting Motor .................. .................. 30

Coolant Temperature Sensor............. ............. 31

Engine Oil Pressure Switch.............. .............. 31

Boost Pressure Sensor (If equipped) ...... ....... 32

Inlet Manifold Temperature Sensor......... ........ 32

Temperature Sensor (DPF Inlet)........... .......... 32

Temperature Sensor (DOC Inlet).......... .......... 33

Speed/Timing Sensor................... .................. 33

This document is printed from SPI². Not for RESALE

![]()

4

KENR9143

Specifications Section

SpecificationsSection

The front of the engine is opposite the flywheel end of

the engine. The left side and the right side of the

engine are determined from the flywheel end.

Number 1 cylinder is the front cylinder of the engine.

i05095429

Engine Design

404F-22 Engine

403F-15T Engine

Illustration 2

g00296424

Cylinder and valve location

(A) Exhaust valve

(B) Inlet valve

Bore .................................................. 84 mm (3.3 inch)

Stroke ............................................. 100 mm (3.9 inch)

Displacement....................................2.216 L (135 in3)

Cylinder arrangement ........................................In-line

Type of combustion ...........................Indirect injection

Compression ratio ............................................. 23.3:1

Number of cylinders .................................................. 4

Valves per cylinder .................................................... 2

Valve lash

Illustration 1

g00852304

Cylinder and valve location

(A) Exhaust valve

(B) Inlet valve

Bore ..................................................84 mm (3.3 inch)

Stroke ...............................................90 mm (3.5 inch)

Displacement......................................1.496 L (91 in3)

Cylinder arrangement ........................................In-line

Type of combustion ...........................Indirect injection

Compression ratio .............................................22.5:1

Number of cylinders .................................................. 3

Valves per cylinder .................................................... 2

Valve lash

Inlet valve............................0.2 mm (0.0078 inch)

Exhaust valve......................0.2 mm (0.0078 inch)

Firing order .....................................................1, 3, 4, 2

When the crankshaft is viewed from the front of the

engine, the crankshaft rotates in the following

direction. .....................................................Clockwise

Inlet valve............................0.2 mm (0.0078 inch)

Exhaust valve...................... 0.2 mm (0.0078 inch)

Firing order .........................................................1, 2, 3

When the camshaft is viewed from the front of the

engine, the camshaft rotates in the following direction.

.....................................................................Clockwise

When the crankshaft is viewed from the front of the

engine, the crankshaft rotates in the following

direction. .....................................................Clockwise

The front of the engine is opposite the flywheel end of

the engine. The left side and the right side of the

engine are determined from the flywheel end.

Number 1 cylinder is the front cylinder of the engine.

When the camshaft is viewed from the front of the

engine, the camshaft rotates in the following direction.

.....................................................................Clockwise

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

5

Specifications Section

404F-22T Engine

Illustration 3

g00296424

Cylinder and valve location

(A) Exhaust valve

(B) Inlet valve

Bore ..................................................84 mm (3.3 inch)

Stroke .............................................100 mm (3.9 inch)

Displacement....................................2.216 L (135 in3)

Cylinder arrangement ........................................In-line

Type of combustion ...........................Indirect injection

Compression ratio .............................................23.5:1

Number of cylinders .................................................. 4

Valves per cylinder .................................................... 2

Valve lash

Illustration 4

g01442026

(1) Torque for the union nuts for the fuel injectors

All models.....................................20 N·m (15 lb ft)

Inlet valve............................0.2 mm (0.0078 inch)

Exhaust valve...................... 0.2 mm (0.0078 inch)

Firing order .....................................................1, 3, 4, 2

When the crankshaft is viewed from the front of the

engine, the crankshaft rotates in the following

direction. .....................................................Clockwise

When the camshaft is viewed from the front of the

engine, the camshaft rotates in the following direction.

.....................................................................Clockwise

Illustration 5

g01442096

(2) Torque for the nut ..........................27 N·m (20 lb ft)

(3) Torque for the banjo bolt..............2.5 N·m (22 lb in)

The front of the engine is opposite the flywheel end of

the engine. The left side and the right side of the

engine are determined from the flywheel end.

Number 1 cylinder is the front cylinder of the engine.

Note: All washers must be replaced when the fuel

lines are removed.

i02959954

i05124091

Fuel Injection Lines

Fuel Injection Pump

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

6

KENR9143

Specifications Section

• 0.20 mm (0.008 inch)

• 0.25 mm (0.010 inch)

• 0.30 mm (0.012 inch)

• 0.35 mm (0.014 inch)

• 0.40 mm (0.016 inch)

• 0.50 mm (0.020 inch)

i05097870

Fuel Injector

Illustration 6

g01329882

Typical example

Type of fuel injection pump .................In-line cassette

Direction of rotation of the camshaft for the fuel

injection pump ...............Clockwise from the drive end

(1) Torque for the mounting nuts and setscrews

............................................................15 N·m (11 lb ft)

(2) Torque for the delivery valve holders ..........42 N·m

(31 lb ft)

Illustration 7

g01335248

Typical example

(3) Shim

(1) Tighten the fuel injectors to the following torque.

............................................................64 N·m (47 lb ft)

The shim adjusts the timing of the fuel injection pump.

A thicker shim regresses the timing. A thinner shim

advances the timing. The timing changes 1 degree for

each 0.10 mm (0.004 inch) difference in the

thickness of the shim. More than one shim can be

used. If the fuel injection pump is reinstalled, new

shims, which have the same thickness as the original

shims, must be installed.

Note: Remove the original seat washer from the hole

for the fuel injector. Do not reuse the original seat

washer.

Note: Apply a 2 mm (0.0787 inch) bead of Loctite

638 to the first 6 mm (0.2362 inch) of the thread to

the fuel injector.

If any of the following new components are installed,

new shims which have the same thickness as the

original shims must be used.

Injector opening pressures for all models

• Camshaft

...................................................14700 kPa (2132 psi)

• Cylinder block

Leakage in 10 seconds ...................................0 drops

The following thicknesses of shims are available:

i05192446

Fuel Transfer Pump

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

7

Specifications Section

i05124109

Rocker Shaft

Illustration 8

g03327470

Typical example

(2) Fuel transfer pump

(1) Tighten the fasteners to the following torque.

......................................................13.7 N·m (121 lb in)

Illustration 10

g01440959

i05097794

Typical example

Lifter Group

Note: Before assembly, lubricate the components

with clean engine oil.

(1) Tighten the setscrews to the following torque.

...........................................................10 N·m (89 lb in)

(2) Tighten the nuts to the following torque. .....33 N·m

(24 lb ft)

Illustration 9

g00692979

Typical example

Clearance between the lifter (1) and the bore in the

engine for the lifter

Standard maximum clearance..............0.058 mm

(0.0023 inch)

Repair limit ......................0.080 mm (0.0031 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

8

KENR9143

Specifications Section

Minimum permissible clearance

......0.030 to 0.093 mm (0.00120 to 0.00366 inch)

Maximum permissible clearance ..............0.2 mm

(0.008 inch)

i05124111

Valve Mechanism Cover

Illustration 11

g01440976

Typical example

(3) Rocker shaft

Diameter of the rocker shaft.... 14.95 to 14.97 mm

(0.5886 to 0.5894 inch)

Service limit..................... 14.87 mm (0.5854 inch)

(4) Tighten the studs to the following torque.

............................................................56 N·m (41 lb ft)

Illustration 13

g01441024

Typical example

(1) Tighten the setscrews for the valve mechanism

cover to the following torque..............10 N·m (89 lb in)

(2) Tighten the setscrews for the connector on the

inlet manifold to the following torque................14 N·m

(10 lb ft)

(3) Tighten the cap nuts for the valve mechanism

cover to the following torque...............14 N·m (10 lb ft)

i05118831

Cylinder Head Valves

Illustration 12

g01440948

Typical example

(5) Tighten the locknut to the following torque.

............................................................14 N·m (10 lb ft)

(6) Rocker arm clearance on the rocker shaft

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

9

Specifications Section

Illustration 14

g00903737

Illustration 15

g00903744

Typical example

Typical example

(5)Exhaust valve guide

(1) Valve spring

(A) Clearance between the exhaust valve and the

valve guide

Standard free length for 403F-15T, 404F-22, and

404F-22T ........................... 35.0 mm (1.378 inch)

403F-15T, 404F-22, and 404F-22T

..........0.050 to 0.075 mm (0.0020 to 0.0030 inch)

Service limit for the standard free length for 403F-

15T, 404F-22, and 404F-22T ................33.5 mm

(1.319 inch)

Service limit.........................0.25 mm (0.010 inch)

(6)Inlet valve guide

Standard test force for 403F-15T, 404F-22, and

404F-22T ........................................79 N (17.8 lb)

(A) Clearance between the inlet valve and the valve

guide

Service limit for the standard test force for 403F-

15T, 404F-22, and 404F-22T ......68.6 N (15.4 lb)

403F-15T, 404F-22, and 404F-22T

..........0.030 to 0.060 mm (0.0012 to 0.0024 inch)

Length under test force for 403F-15T, 404F-22,

and 404F-22T ....................30.4 mm (1.197 inch)

Service limit...........................0.2 mm (0.008 inch)

(7) Exhaust valve stem

(2) Valve guide seal for the exhaust valve

Identification ...........................Black garter spring

Label on the black garter spring................... “EX”

Diameter of the exhaust valve stem for 403F-15T,

404F-22, and 404F-22T ........6.940 to 6.955 mm

(0.2732 to 0.2738 inch)

(3) Valve guide seal for the inlet valve

Identification ...........................Silver garter spring

(4)Valve spring recess for the valve spring

Service limit.........................6.84 mm (0.269 inch)

(8) Inlet valve stem

Diameter of the inlet valve stem for 403F-15T,

404F-22, and 404F-22T ........6.955 to 6.970 mm

(0.27382 to 0.27441 inch)

Service limit.........................6.89 mm (0.271 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

10

KENR9143

Specifications Section

Illustration 16

g00845823

Typical example

(B) Thickness of the valve head .... 0.925 to 1.075 mm

(0.03642 to 0.04232 inch)

Service limit .................................0.5 mm (0.020 inch)

Illustration 18

g00903760

Typical example

(D) Valve seat angle ..................................45 degrees

(E) Contact face

Inlet valve

403F-15T ...................................1.66 to 1.87 mm

(0.0653 to 0.0736 inch)

404F-22, and 404F-22T ............1.50 to 2.00 mm

(0.0591 to 0.0790 inch)

Service limit...........................2.5 mm (0.098 inch)

Exhaust valve

403F-15T ...................................1.66 to 1.73 mm

(0.0653 to 0.0681 inch)

404F-22, and 404F-22T ............1.94 to 2.16 mm

(0.0764 to 0.0850 inch)

Illustration 17

g00903773

Service limit...........................2.5 mm (0.098 inch)

Typical example

(C) Valve depth below the cylinder head face

i05121549

Cylinder Head

Inlet and exhaust valves for 403F-15T, 404F-22,

and 404F-22T ............................0.65 to 0.95 mm

(0.0256 to 0.0374 inch)

Service limit...........................1.8 mm (0.071 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

11

Specifications Section

Tightening Procedure for the

Cylinder Head

403F-15T Engine

Illustration 19

g00819698

Typical example

(1)Dowel pins

The dowel pins in the cylinder block hold the cylinder

head gasket in the correct position when the cylinder

head is installed.

Illustration 20

g01317351

Use the following procedure in order to tighten the

bolts for the cylinder head.

(2)Cylinder head gasket

Table 1

1. Put clean engine oil on the threads of the bolts.

The bolts are tightened in the numerical sequence

that is shown in Illustration 20 .

Selection of Head Gasket for the 403F-15T Engine

Piston Height above Top Face of Cylinder Gasket Thickness

Block

Torque for bolts.................................101 N·m (75 lb ft)

0.60 to 0.69 mm (0.0236 to 0.0272 inch)

1.3 mm

(0.051 inch)

2. Repeat the procedure in step 1 to ensure that all of

0.70 to 0.79 mm (0.0276 to 0.0311 inch)

1.4 mm

(0.055 inch)

the bolts are tightened to the correct torque.

404F-22, and 404F-22T Engines

Table 2

Selection of Head Gasket for the 404F-22, and 404F-22T

Engines

Piston Height below Top Face of Cylinder Gasket Thickness

Block

+0.3 to 0.4 mm (+0.0118 to 0.016 inch)

+0.4 to 0.5 mm (+0.016 to 0.020 inch)

+0.5 to 0.6 mm (+0.020 to 0.024 inch)

1.1 mm

(0.043 inch)

1.2 mm

(0.047 inch)

1.3 mm

(0.051 inch)

(3)The stamped marking on the cylinder head gasket

must face upward. The stamped marking ensures

that the cylinder head gasket is installed correctly.

Illustration 21

g01309552

Use the following procedure in order to tighten the

bolts for the cylinder head.

1. Put clean engine oil on the threads of the bolts.

The bolts are tightened in the numerical sequence

that is shown in Illustration 21 .

Torque for bolts.................................101 N·m (75 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

12

KENR9143

Specifications Section

2. Repeat the procedure in step 1 to ensure that all of

the bolts are tightened to the correct torque.

Measuring the Distortion of the

Cylinder Head

Illustration 22

g00900977

Illustration 23

g00921767

Typical example

(1) Torque for the banjo bolt for the oil supply line

.........................................................18 N·m (13.3 lb ft)

Distortion of the cylinder head...........0.00 to 0.05 mm

(0.000 to 0.002 inch)

(2) Torque for the nuts that secure the turbocharger to

the exhaust manifold ..........................25 N·m (18 lb ft)

Maximum service limit ...............0.12 mm (0.005 inch)

Maximum limit for regrinding the cylinder head

...................................................0.15 mm (0.006 inch)

(3) Torque for the setscrews for the oil drain tube

..............................................................10 N·m (7 lb ft)

Note: Use a straight edge and a feeler gauge to

check the six positions for distortion.

i05192977

Air Pump (ARD Air)

Refer to Systems Operation, Testing and Adjusting,

“Cylinder Head - Inspect” for the procedures for

measuring the cylinder head.

Note: Check the valve depth below the cylinder head

face. Refer to Specifications, “Cylinder Head Valves”

for valve depth.

i02961020

Turbocharger

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

13

Specifications Section

i05192969

Exhaust Cooler (NRS)

(If equipped)

Illustration 24

g03329697

Typical example

(1) Tighten the bolts to the following torque.

..........................................................3.1 N·m (27 lb in)

Illustration 26

g03329691

Typical example

(1) Tighten the nut to the following torque.....14.7 N·m

(11 lb ft)

(2) Tighten the bolt to the following torque.

.........................................................14.7 N·m (11 lb ft)

Illustration 25

g03329702

Typical example

(2) Tighten the fasteners to the following torque.

............................................................25 N·m (18 lb ft)

(3) Tighten the fasteners to the following torque.

............................................................25 N·m (18 lb ft)

Note: Bolt (4) should be tightened in order to achieve

the correct belt tension. Refer to Specifications, “Belt

Tension Chart” for the correct belt tension.

Illustration 27

g03329692

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

14

KENR9143

Specifications Section

(3) Tighten the fasteners to the following torque.

.........................................................14.7 N·m (11 lb ft)

(4) Tighten the fasteners to the following torque.

.........................................................14.7 N·m (11 lb ft)

(5) Tighten the clamps to the following torque.

.............................................................3 N·m (27 lb in)

i05167590

Exhaust Manifold

Illustration 29

g03327839

Typical example

(1) Tighten the setscrews to the following torque.

..........................................................9.8 N·m (87 lb in)

Note: The glow plug (2) for the ARD can be replaced.

Refer to Operation and Maintenance Manual, “Glow

Plugs (ARD Combustion) - Replace” for the correct

procedure.

Illustration 28

g00899933

(3) Tighten the pipe to the following torque. .....20 N·m

(15 lb ft)

Typical example

(1) Gasket

(4) Tighten the temperature sensor to the following

torque..................................................30 N·m (22 lb ft)

(2) Tighten the fasteners for the exhaust manifold to

the following torque.............................25 N·m (18 lb ft)

(5) Tighten the studs to the following torque.

............................................................25 N·m (18 lb ft)

i05192974

Exhaust Combustion (ARD)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

15

Specifications Section

(11) Tighten the bolts to the following torque.

.........................................................32.4 N·m (24 lb ft)

i05118731

Camshaft

Illustration 30

g03329342

Typical example

(6) Tighten the nuts to the following torque. .....25 N·m

(18 lb ft)

Illustration 32

g00819857

Typical example

(7) Tighten the bolts to the following torque......25 N·m

(18 lb ft)

(1) Height of the camshaft lobe for the inlet and

exhaust valves

403F-15T, 404F-22, and 404F-22T

......34.453 to 34.507 mm (1.3564 to 1.3585 inch)

Service limit

403F-15T, 404F-22, and 404F-22T ....... 33.7 mm

(1.3270 inch)

(2) Height of the camshaft lobe for the fuel injection

pump

403F-15T, 404F-22, and 404F-22T

......41.940 to 42.060 mm (1.6512 to 1.6559 inch)

Service limit

403F-15T, 404F-22, and 404F-22T ....... 41.8 mm

(1.6450 inch)

(3) Height of the camshaft lobe for the fuel priming

pump

Illustration 31

g03329350

403F-15T, 404F-22, and 404F-22T

......31.900 to 32.000 mm (1.2559 to 1.2598 inch)

Typical example

(8) Tighten the bolts to the following torque......50 N·m

(37 lb ft)

Service limit

403F-15T, 404F-22, and 404F-22T ....... 30.0 mm

(1.1810 inch)

(9) Tighten the nuts to the following torque. .....25 N·m

(18 lb ft)

(10) Tighten the bolts to the following torque.

............................................................25 N·m (18 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

16

KENR9143

Specifications Section

Illustration 33

g00295323

Illustration 34

g01297670

Typical example

Typical example

(A)Actual camshaft lobe lift

(B)Height of the camshaft lobe

(C)Base circle

(4) Tighten the setscrews for the retainer plate for the

camshaft to the following torque........11 N·m (97 lb in)

(5)Retainer plate for the camshaft

(6)Camshaft gear

To determine the lobe lift, use the procedure that

follows:

1. Measure the height of the camshaft lobe (B).

2. Measure the base circle (C).

3. Subtract the base circle that is found in Step 2 from

the height of the camshaft lobe that is found in

Step 1. The difference is the actual camshaft lobe

lift.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

17

Specifications Section

i02961066

Engine Oil Lines

Illustration 35

g01093847

Typical example

(1) Engine oil line

(2) Washers

Note: The washers must be replaced with new

washers when the engine oil line is removed.

(3) Torque for the banjo bolts................12 N·m (9 lb ft)

i05105509

Engine Oil Relief Valve

Illustration 36

g00820218

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

18

KENR9143

Specifications Section

Note: When the engine oil relief valve is installed,

ensure that all components are clean. Lightly

lubricate all components with clean engine oil.

(6) Inner rotor

Number of lobes ................................................. 4

(7) Spring

(1) A new O-ring should be used when the engine oil

relief valve is installed.

(8) Outer rotor

Number of lobes ................................................. 5

(2) Tighten the engine oil relief valve to the following

torque..................................................64 N·m (47 lb ft)

The engine oil pressure at the engine oil relief valve is

the following value.

403F-15T ...............262 to 359 kPa (38 to 52 psi)

404F-22, and 404F-22T ..............352 to 448 kPa

(51 to 65 psi)

Note: Always remove the engine oil relief valve

before removing or installing the crankshaft. Damage

to the engine oil relief valve or damage to the

crankshaft may occur.

i05164987

Engine Oil Pump

Illustration 38

g00459701

NOTICE

If the front housing is not installed, do not turn the

crankshaft. Damage to the engine may occur.

(A) Clearance between the inner rotor and the outer

rotor is the following value.................0.01 to 0.15 mm

(0.0004 to 0.006 inch)

Service Limit............................0.25 mm (0.0098 inch)

(9) Bushing

(10) Idler gear

(11) Thrust washer

Illustration 37

g00458938

Idler gear and components of the engine oil pump

Type ......................................................Gerotor pump

(1) Circlip

(2) Collar

(3) Spring

(4) Shim

(5) Oil pump cover

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

19

Specifications Section

Illustration 40

g00820013

(1) Gasket

(2) Engine oil pan

(3) Washer

Illustration 39

g01088627

(4) Tighten the bolts for the engine oil pan to the

(12) Dial indicator

following torque.....................................11 N·m (8 lb ft)

(B) When the components of the oil pump are

(5) Tighten the drain plugs of the engine oil pan to the

following torque...................................35 N·m (26 lb ft)

installed on the front housing, measurement (B)

between C-clip (1) and collar (2) must not exceed the

following distance. ............................. 0.10 to 0.15 mm

(0.004 to 0.006 inch)

Note: Install a new gasket (1) when the engine oil

pan is removed or replaced.

Oil Suction Tube and Oil Strainer

Service limit ...............................0.20 mm (0.008 inch)

The distance between the faces is adjusted with

shims (4). The following sizes of shims are available:

• 0.10 mm

• 0.15 mm

• 0.20 mm

• 0.50 mm

i02586871

Engine Oil Pan

Illustration 41

g00820021

(1) O-ring

(2) Oil suction tube

(3) Tighten the bolts for the oil strainer to the following

torque....................................................11 N·m (8 lb ft)

(4) Strainer

Note: Install a new O-ring (1) in the hole of the

cylinder block when the oil suction tube is removed or

replaced.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

20

KENR9143

Specifications Section

i05192960

403F-15Tand 404F-22 engines.........80° to 84°C

(176° to 183°F)

Crankcase Breather

404F-22T engines ......................... 82 °C (180 °F)

Fully open temperature of the water temperature

regulator................................................ 95 °C (203 °F)

Water Temperature Regulator

Housing for 403F-15T, 404F-22, and

404F-22T Engines

Illustration 42

g03327834

Typical example

(1) Tighten the setscrews to the following torque.

..........................................................7.5 N·m (66 lb in)

Illustration 44

g00820265

i05105490

Water Temperature Regulator

Illustration 45

g01114379

Water temperature regulator for naturally aspirated

engines

Illustration 43

g00877006

Typical example

Opening temperature of the water temperature

regulator

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

21

Specifications Section

Service limit .........................84.200 mm (3.3150 inch)

Illustration 46

g01114381

Water temperature regulator for turbocharged

engines

Illustration 48

g00901145

Typical example

Note: Ensure that the water temperature regulator is

seated correctly in the housing.

Flatness of the top of the cylinder block ......Less than

0.05 mm (0.002 inch)

Note: Ensure that the jiggle pin (1) on the water

temperature regulator is correctly positioned. Refer to

illustrations 45 and 46 .

Service limit ...............................0.12 mm (0.005 inch)

Note: Use a straight edge and a feeler gauge to

check the six positions for flatness.

(1) Torque for the two setscrews for the water

temperature regulator housing ...........14 N·m (10 lb ft)

Note: The front bush for the crankshaft must be

installed with the chamfer toward the cylinder block.

Ensure that the oil hole in the front bush for the

crankshaft is aligned with the oil hole in the cylinder

block.

(2) Cover

(3) Water temperature regulator

(4) Gasket

i05095147

i05094774

Crankshaft

Cylinder Block

Illustration 47

g00904878

Typical example

(1) Diameter of the bore in the cylinder block

.............84.000 to 84.019 mm (3.3071 to 3.3078 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

22

KENR9143

Specifications Section

Note: The top thrust washer (3) is used only on the

404F-22, and 404F-22T engines

Ensure that the oil grooves of all of the thrust washers

are toward the crankshaft.

Illustration 51

g00904925

Typical example

Illustration 49

g01113243

Typical crankshaft for a three cylinder engine

(4) Tighten the retaining bolts for the crankshaft to the

following torque...................................52 N·m (38 lb ft)

(5) Tighten the allen head screws to the following

torque..................................................27 N·m (20 lb ft)

Crankshaft end play........................... 0.10 to 0.30 mm

(0.0040 to 0.0118 inch)

Service limit .............................0.50 mm (0.0197 inch)

Note: If the crankshaft end play exceeds the service

limit, check the thrust washers for wear.

Refer to Specifications, “Connecting Rod Bearing

Journal” for information on the connecting rod bearing

journals of the crankshaft.

Refer to Specifications, “Main Bearing Journal” for

information on the main bearing journals of the

crankshaft.

i05124089

Connecting Rod Bearing

Journal

Illustration 50

g00904902

Typical crankshaft for a four cylinder engine

(1) Tighten the bolts of the holder for the main bearing

to the following torque.........................52 N·m (38 lb ft)

(2) Thrust washers

Table 3

403F-15T, 404F-22, and 404F-22T

Standard thickness ..................... 2.95 to 3.00 mm

(0.1161 to 0.1181 inch)

Diameter of the 403F-15T, 404F-22, and 404F-22T Connecting

Rod Bearing Journals

Journals

Diameter

Service limit

51.964 to 51.975 mm

(2.04582 to 2.04626 inch)

51.90 mm

(2.0433 inch)

Service limit........................2.80 mm (0.1102 inch)

(3)Top thrust washer

Standard

(continued)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

23

Specifications Section

(Table 3, contd)

Undersize

0.25 mm

(0.010 inch)

51.714 to 51.725 mm

(2.03598 to 2.03641 inch)

51.65 mm

(2.0335 inch)

Undersize

0.50 mm

(0.020 inch)

51.464 to 51.475 mm

(2.02614 to 2.02660 inch) (2.0236 inch)(1)

51.40 mm

(1)

If the diameter of the connecting rod bearing journal is less than

the maximum undersize service limit, the crankshaft must be

replaced.

Clearance between the connecting rod bearing and

the connecting rod bearing journal

Standard clearance

403F-15T, 404F-22, and 404F-22T

......0.035 to 0.085 mm (0.00138 to 0.00335 inch)

Service limit....................... 0.20 mm (0.0079 inch)

i05124030

Illustration 52

g00693257

Main Bearing Journal

Typical example

(1) Connecting rod

(2) Piston pin bearing

Table 4

Clearance between the piston pin and the piston

pin bearing (All models) ..........0.010 to 0.025 mm

(0.00040 to 0.00099 inch)

Diameter of Main Bearing Journals

Journals

Diameter

Service limit

67.957 to 67.970 mm

(2.67550 to 2.67597 inch) (2.6732 inch)

67.90 mm

Service limit

403F-15T, 404F-22, and 404F-22T ....... 0.10 mm

(0.004 inch)

Standard

Clearance between the main bearing and the main

bearing journal........................0.044 mm to 0.102 mm

(0.0017 inch to 0.0040 inch)

(3) Torque for the nut and the bolt.......52 N·m (38 lb ft)

(4) Connecting rod bearing

Service limit .............................0.20 mm (0.0079 inch)

Clearance between the connecting rod bore and

the connecting rod bearing ......... 0.10 to 0.30 mm

(0.004 to 0.012 inch)

i05124033

Connecting Rod

Service limit.......................0.70 mm (0.0276 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

24

KENR9143

Specifications Section

Markings on the Connecting Rod

(2)The Shibaura name that is on the inside of the

piston must align with the stamped number on the

connecting rod.

Piston and Piston Rings

Illustration 53

g00555416

Typical example

The pistons and connecting rods are matched to

each cylinder. Note the position of each connecting

rod and piston for correct assembly.

Identification marks (1) on the connecting rod and on

the connecting rod cap must be matched and aligned.

When the connecting rod is installed correctly, the

marks should face the right side of the engine.

Illustration 55

g00845969

Refer to Testing and Adjusting, “Connecting Rod -

Inspect” for the procedure to measure distortion and

parallelism of the connecting rod.

Typical example

Use a feeler gauge to measure the clearance

between the piston ring groove and the piston ring. If

the clearance is greater than the service limit, use a

new piston ring and check the clearance.

i05124083

Piston and Rings

If the clearance is within the service limit, renew the

piston rings. If the clearance is outside of the service

limit, renew the piston.

(1) Top piston ring

Markings on the Piston

Shape of top ring (A)

Naturally aspirated ..............................Barrel face

Turbocharged .................................Half keystone

403F-15T, and 404F-22

Clearance between piston ring groove and top

piston ring.....................................0.07 to 0.11 mm

(0.0028 to 0.0043 inch)

Service limit for clearance of top piston ring

.......................................... 0.25 mm (0.0098 inch)

Gap of top piston ring..................0.20 to 0.35 mm

(0.0079 to 0.0138 inch)

Service limit for gap of top piston ring....... 1.0 mm

(0.039 inch)

Illustration 54

g00845975

Typical example

Note: It is difficult to measure the wear of the top

piston ring on the 404F-22T turbocharged engines.

When either the intermediate ring or the oil control

ring is outside the service limit, renew all of the rings.

(1)The chamber that is on the top of the piston must

face the right side of the engine.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

25

Specifications Section

Note: Install the letters “T” or “RN” toward the top of

the piston. New top piston rings have a red

identification mark. The identification mark must be

on the left of the ring gap when the top piston ring is

installed on an upright piston.

The oil control ring has two components. The two

components of the oil control ring are installed in the

following order.

1. Spring (D)

Note: New top piston rings for the 404F-22T have a

yellow identification mark. The identification mark

must be on the left of the ring gap when the top piston

ring is installed on an upright piston.

2. Oil control ring (C)

Note: A latch pin is used in order to hold both ends of

the spring of the oil control ring in position. The ends

of the spring of the oil control ring must be 180

degrees opposite the end gap of the oil control ring.

Note: The top surface of the piston ring should be

equally distant from the top face of the cylinder block

at all points before the piston ring end gap is

measured with a feeler gauge.

Note: The top surface of the piston ring should be

equally distant from the top face of the cylinder block

at all points before the piston ring end gap is

measured with a feeler gauge.

(2) Intermediate ring

(4) Piston

Shape of intermediate ring (B) .................... Taper

403F-15T, 404F-22, and 404F-22T

Diameter of the piston skirt

......83.948 to 83.963 mm (3.3050 to 3.3056 inch)

403F-15T, 404F-22, and 404F-22T

Clearance between piston ring groove and

intermediate ring .........................0.04 to 0.08 mm

(0.0016 to 0.0032 inch)

Service limit.........................83.7 mm (3.295 inch)

Service limit for clearance of intermediate ring

..........................................0.25 mm (0.0098 inch)

Clearance of the piston skirt to the cylinder wall

............................................0.0380 to 0.0720 mm

(0.00150 to 0.00283 inch)

403F-15T, and 404F-22

gap of the intermediate ring ............ 0.2 to 0.4 mm

(0.0079 to 0.0157 inch)

Service limit.........................0.25 mm (0.010 inch)

Diameter of the piston pin

......27.994 to 28.000 mm (1.1021 to 1.1024 inch)

404F-22T gap of the intermediate ring

...................... 0.5 to 0.7 mm (0.020 to 0.023 inch)

Service limit.....................27.98 mm (1.1016 inch)

Service limit for gap of intermediate ring

.............................................. 1.2 mm (0.047 inch)

Clearance between the hole for the piston pin

and the piston pin................−0.001 to +0.011 mm

(−0.0004 to +0.0004 inch)

Note: Install the word “Top” toward the top of the

piston. New intermediate rings have a green

identification mark. The identification mark must be

on the left of the ring gap when the intermediate ring

is installed on an upright piston.

Service limit.......................0.02 mm (0.0008 inch)

Refer to Specifications, “Cylinder Head” for the piston

height for a given gasket thickness.

Note: The top surface of the piston ring should be

equally distant from the top face of the cylinder block

at all points before the piston ring end gap is

measured with a feeler gauge.

i05192371

Balancer

(3) Oil control ring

403F-15T, 404F-22, and 404F-22T

Clearance between piston ring groove and oil

control ring ..................................0.02 to 0.06 mm

(0.0008 to 0.0024 inch)

Service limit for clearance of oil control ring

..........................................0.15 mm (0.0059 inch)

Gap of oil control ring..................0.25 to 0.50 mm

(0.0098 to 0.0197 inch)

Service limit for gap of oil control ring....... 1.0 mm

(0.039 inch)

This document is printed from SPI². Not for RESALE

![]()

26

KENR9143

Specifications Section

Illustration 56

g03340077

Typical example

(1) Tighten the setscrews that retain the balancer to

the cylinder block to the following torque..........52 N·m

(38 lb ft)

Illustration 57

g01308682

The backlash between the crankshaft gear and the

balancer gear......................................... 0.2 to 0.4 mm

(0.00787 to 0.01575 inch)

Typical example

(1) Locator hole

(2) Locator pin

(3) Front housing

Note: The balancer has shims to reduce the backlash

on the balancer gear.

i02613910

(4) Tighten the setscrews and nuts to the following

torque....................................................10 N·m (7 lb ft)

Housing (Front)

Note: Note the positions of the setscrews when the

bolts are removed. The setscrews have different

lengths.

(5) Seal protector

i05105472

Gear Group (Front)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

27

Specifications Section

Table 5

(3) Timing mark on the camshaft gear

Injection timing

(4) Timing mark on the idler gear

Engine

Maximum rated en-

gine speed

Injection timing

(BTDC)(1)

Minimum backlash for all gears..................... 0.08 mm

(0.003 inch)

403F-15T Industrial

engine

2400

2800

3000

16° ± 1°

16° ± 1°

16° ± 1°

Maximum backlash for all gears....................0.25 mm

(0.010 inch)

403F-15T Industrial

engine

Note: If the backlash is greater than the maximum

backlash, replace the camshaft gear, the idler gear,

and the crankshaft gear.

403F-15T Industrial

engine

404F-22 engine

1800

2400

14.5° ± 1°

18° ± 1°

When the idler gear is installed on the shaft of the oil

pump, align a timing mark on idler gear (4) with the

timing mark on crankshaft gear (2). Also, align the

other timing mark on idler gear (4) with the timing

mark on camshaft gear (3).

404F-22 Industrial

engine

404F-22 Industrial

engine

2600

2800

3000

17° ± 1°

17° ± 1°

18° ± 1°

404F-22 Industrial

engine

i02590383

Flywheel

404F-22 Industrial

engine

404F-22T engine

1800

2600

15° ± 1°

18° ± 1°

404F-22T Industrial

engine

404F-22T Industrial

engine

2800

3000

19° ± 1°

20° ± 1°

404F-22T Industrial

engine

(1)

Before Top Dead Center

Illustration 59

g00820355

(1) Heat the flywheel ring gear to the following

temperature. ................120° to 150°C (248° to 302°F)

Note: If the ring gear is excessively worn, renew the

ring gear. If excessive wear is not present, remove

the ring gear and install the ring gear at 90 degrees

from the original position. Heat the ring gear evenly.

(2) Tighten the setscrews on the flywheel to the

following torque...................................74 N·m (55 lb ft)

Maximum flywheel runout..........0.20 mm (0.008 inch)

Illustration 58

g01298853

i05164369

Typical example

Flywheel Housing

(1) Feeler gauge

(2) Timing mark on the crankshaft gear

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

28

KENR9143

Specifications Section

Illustration 60

g01442020

Typical example

(1) Tighten the setscrews for the back plate to the

following torque...................................25 N·m (19 lb ft)

(2) Tighten the setscrews for the flywheel housing to

the following torque.............................25 N·m (19 lb ft)

i05164995

Crankshaft Pulley

Illustration 61

g00904688

Typical example

(1) Tighten the crankshaft pulley nut to the following

torque.............................................304 N·m (224 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9143

29

Specifications Section

i05221013

Belt Tension Chart

Table 6

Belt Tension Chart for Alternator and Fan Belts

Gauge Reading

Initial Belt Tension

(1)

Used Belt Tension

(2)

400 to 489 N (90 to 110 lb)

Initial Belt Tension refers to a new belt.

267 to 356 N (60 to 80 lb)

(1)

(2)

Used Belt Tension refers to a belt that has been in operation for 30 minutes or more at the rated speed.

Table 7

Belt Tension Chart for Air Pump Belts

Gauge Reading

Initial Belt Tension(1)

Used Belt Tension(2)

310 N (69 lb)

220 N (49 lb)

(1)

(2)

Initial Belt Tension refers to a new belt.

Used Belt Tension refers to a belt that has been in operation for 30 minutes or more at the rated speed.

i02590411

i05192976

Fan Drive

Engine Lifting Bracket

Illustration 62

g00904732

(1) Tighten the allen head screws for the adapter to

the following torque...............................11 N·m (8 lb ft)

(2) Tighten the setscrews for the fan to the following

torque....................................................11 N·m (8 lb ft)

Illustration 63

g03329689

Typical example

(1) Tighten the bolts to the following torque......25 N·m

(18 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

30

KENR9143

Specifications Section

(2) Tighten the bolts to the following torque......50 N·m

(37 lb ft)

Tighten the nut on the terminal to the following

torque.........................................4.4 N·m (39 lb in)

(2) Terminal “D+”

Tighten the nut on the terminal to the following

torque.........................................4.4 N·m (39 lb in)

(3) Terminal “B+”

Tighten the nut on the terminal to the following.

......................................................7 N·m (62 lb in)

The rotation of the alternator is clockwise when the

alternator is viewed from the pulley.

The regulator of the alternator is sealed. The

regulator is a nonserviceable part.

Polarity ...........................Negative ground to the case

Rotation ...............................................Either direction

Output voltage .....................................................14 V

Rated voltage .......................................................12 V

Rated current output ...................................60 or 85 A

Illustration 64

g03329690

Typical example

(3) Tighten the bolts that secure the bracket to the

following torque...................................50 N·m (37 lb ft)

i05124496

Electric Starting Motor

i05124451

Alternator and Regulator

Starting Motor

Illustration 66

g00379835

Starting motor and starting motor solenoid

No load conditions at 25°C (77°F)

Rpm with no load ......................4000 to 6000 rpm

Maximum current ........................................540 A

Current draw with no load ...........................130 A

Voltage .......................................................11.5 V

Rated voltage ................................................12 V

Illustration 65

g03327359

Typical example

(1) Terminal “W”

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

31

Specifications Section

Power rating ........................................................2 kW

Power rating ........................................................2 kW

Minimum average cranking rpm ........................... 130

Starting motor solenoid

i05164981

Engine Oil Pressure Switch

Pull-in current .............................................54.5 A

Hold-in current ............................................10.5 A

(1) Tighten the battery terminal nut to the following

torque..................................................15 N·m (11 lb ft)

(2) Tighten the two mounting bolts to the following

torque..................................................50 N·m (37 lb ft)

(3) Tighten the nut for the switch terminal to the

following torque................1.0 to 1.3 N·m (9 to 12 lb in)

Maximum resistance of the starter cable at 20°C

(68°F) and at 12 V .......................................0.04 ohms

i05189560

Coolant Temperature Sensor

Illustration 68

g01335504

Typical example

Note: The engine oil pressure switch can be found in

two positions.

(1) Engine oil pressure switch that is located on the

valve mechanism cover

Torque for the engine oil pressure switch

....................................................11 N·m (97 lb in)

403F-15T, 404F-22, and 404F-22T ............(Amp)

Brown connector

Pressure rating

403F-15T, 404F-22, 404F-22T ..............29.4 kPa

(4.26 psi)

Illustration 67

g03325662

Typical example

(2) Engine oil pressure switch that is located on the

cylinder block

(1) Tighten the coolant temperature sensor to the

following torque................................17.2N·m (13 lb ft)

Torque for the engine oil pressure switch

.....................................................23 N·m (17 lb ft)

403F-15T, 404F-22, and 404F-22T ............(Amp)

Black connector

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

32

KENR9143

Specifications Section

Pressure rating

403F-15T, 404F-22, and 404F-22T .......68.9 kPa

(10.0 psi)

i05189692

Boost Pressure Sensor

(If equipped)

Illustration 70

g03325818

Typical example

(1) Tighten the sensor to the following torque.

.........................................................17.2 N·m (13 lb ft)

i05181637

Temperature Sensor (DPF

Inlet)

Illustration 69

g03325764

Typical example

(1) Tighten the fasteners that secure the sensor to the

following torque....................................3 N·m (27 lb in)

i05189704

Inlet Manifold Temperature

Sensor

Illustration 71

g03322423

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR9143

33

Specifications Section

(1) Tighten the temperature sensor to the following

torque..................................................30 N·m (22 lb ft)

i05181638

Temperature Sensor (DOC

Inlet)

Illustration 73

g03323793

Typical example

Illustration 72

g03322426

Typical example

(1) Tighten the temperature sensor to the following

torque..................................................30 N·m (22 lb ft)

i05189664

Speed/Timing Sensor

Illustration 74

g03323794

Typical example

(1) (2) Tighten the sensor to the following torque.

.............................................................7 N·m (62 lb in)

i05124491

Glow Plugs

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

34

KENR9143

Specifications Section

Illustration 75

g00904843

Typical example

(1) Tighten the nut on the bus bar to the following

torque................................................1.2 N·m (11 lb in)

(2) Tighten the glow plugs to the following torque.

............................................................18 N·m (13 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9143

35

Index Section

Index

A

F

Air Pump (ARD Air).......................................... 12

Alternator and Regulator.................................. 30

Fan Drive......................................................... 29

Flywheel .......................................................... 27

Flywheel Housing............................................ 27

Fuel Injection Lines............................................ 5

Fuel Injection Pump........................................... 5

Fuel Injector....................................................... 6

Fuel Transfer Pump........................................... 6

B

Balancer .......................................................... 25

Belt Tension Chart ........................................... 29

Boost Pressure Sensor (If equipped) .............. 32

G

C

Gear Group (Front).......................................... 26

Glow Plugs ...................................................... 33

Camshaft......................................................... 15

Connecting Rod............................................... 23

Markings on the Connecting Rod................. 24

Connecting Rod Bearing Journal..................... 22

Coolant Temperature Sensor........................... 31

Crankcase Breather......................................... 20

Crankshaft....................................................... 21

Crankshaft Pulley ............................................ 28

Cylinder Block.................................................. 21

Cylinder Head.................................................. 10

Measuring the Distortion of the Cylinder Head

................................................................... 12

Tightening Procedure for the Cylinder Head

....................................................................11

Cylinder Head Valves ........................................ 8

H

Housing (Front)................................................ 26

I

Important Safety Information............................. 2

Inlet Manifold Temperature Sensor.................. 32

L

Lifter Group........................................................ 7

M

E

Main Bearing Journal....................................... 23

Electric Starting Motor ..................................... 30

Starting Motor............................................... 30

Engine Design ................................................... 4

403F-15T Engine .......................................... 4

404F-22 Engine ............................................ 4

404F-22T Engine .......................................... 5

Engine Lifting Bracket...................................... 29

Engine Oil Lines............................................... 17

Engine Oil Pan................................................. 19

Oil Suction Tube and Oil Strainer................. 19

Engine Oil Pressure Switch............................. 31

Engine Oil Pump.............................................. 18

Engine Oil Relief Valve.................................... 17

Exhaust Combustion (ARD) ............................ 14

Exhaust Cooler (NRS) (If equipped)................ 13

Exhaust Manifold............................................. 14

P

Piston and Rings ............................................. 24

Markings on the Piston ................................ 24

Piston and Piston Rings............................... 24

R

Rocker Shaft...................................................... 7

S

Specifications Section ....................................... 4

Speed/Timing Sensor...................................... 33

This document is printed from SPI². Not for RESALE

![]()

36

KENR9143

Index Section

T

Table of Contents............................................... 3

Temperature Sensor (DOC Inlet)..................... 33

Temperature Sensor (DPF Inlet)...................... 32

Turbocharger................................................... 12

V

Valve Mechanism Cover.................................... 8

W

Water Temperature Regulator ......................... 20

Water Temperature Regulator Housing for

403F-15T, 404F-22, and 404F-22T Engines

................................................................... 20

This document is printed from SPI². Not for RESALE

![]()

This document is printed from SPI². Not for RESALE

©2013 Perkins Engines Company Limited

All Rights Reserved

This document is printed from SPI². Not for RESALE

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska