珀金斯Perkins1206F-E70TA(TTA)技術資料(英文)

詳細描述

Specifications

1206F-E70TA and 1206F-E70TTA

Industrial Engines

BM (Engine)

BN (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

UENR0675

3

Table of Contents

Table of Contents

Accessory Drive....................... ....................... 42

Front Housing and Covers............... ............... 42

Gear Group (Front)..................... .................... 43

Flywheel .......................................................... 44

Flywheel Housing...................... ..................... 44

Belt Tensioner......................... ........................ 45

Refrigerant Compressor................. ................ 45

Fan Drive............................ ............................ 46

Engine Lifting Bracket................... .................. 46

Alternator............................ ............................ 46

Starter Motor.......................... ......................... 48

Nitrogen Oxide Sensor .................. ................. 50

Coolant Temperature Sensor............. ............. 51

Engine Oil Pressure Sensor.............. ............. 51

Boost Pressure Sensor.................. ................. 51

Atmospheric Pressure Sensor............ ............ 52

Inlet Manifold Temperature Sensor......... ........ 52

Turbocharger Exhaust Temperature Sensor . . 53

Temperature Sensor (DPF Inlet)........... .......... 53

Temperature Sensor (Exhaust)............ ........... 54

Pressure Sensor (NOx Reduction System).. .. 54

Temperature Sensor (NOx Reduction System)55

Soot Antenna......................... ......................... 55

Speed/Timing Sensor................... .................. 56

Electronic Control Module ............... ............... 56

Electronic Control (Diesel Exhaust Fluid).... ... 57

Glow Plugs .......................... ........................... 57

Air Compressor (Twin Cylinder Compressor) 58

Air Compressor (Single Cylinder)......... ......... 59

SpecificationsSection

Engine Design ......................... ......................... 4

Fuel Injection Lines...................... ..................... 4

Fuel Injection Pump..................... ..................... 5

Fuel Injectors.......................... .......................... 6

Fuel Transfer Pump (Electric Transfer Pump) . 6

Fuel Filter Base (Single Secondary Fuel Filter

Base) ............................... ............................... 7

Fuel Filter Base (Twin Secondary Fuel Filter

Base) ............................... ............................... 7

Fuel Filter Base (Primary Fuel Filter Base)... ... 8

Fuel Manifold (Rail)...................... ..................... 9

Lifter Group............................ ........................... 9

Rocker Shaft........................... .......................... 9

Valve Mechanism Cover................. .................11

Cylinder Head Valves ................... ...................11

Cylinder Head......................... ........................ 12

Turbocharger (Series Turbochargers)...... ...... 14

Turbocharger (Single Turbocharger)....... ....... 17

Injector (Diesel Exhaust Fluid)............ ............ 18

Manifold (Diesel Exhaust Fluid)........... ........... 20

Diesel Exhaust Fluid Tank ............... ............... 20

Diesel Exhaust Fluid Pump .............. .............. 21

Exhaust Gas Valve (NRS) ............... ............... 21

Exhaust Cooler (NRS).................. .................. 23

Exhaust Manifold...................... ...................... 25

Flexible Exhaust Pipe................... .................. 26

Camshaft............................ ............................ 26

Camshaft Bearings..................... .................... 27

Engine Oil Filter Base................... .................. 28

Engine Oil Cooler...................... ...................... 28

Engine Oil Pump....................... ...................... 29

Engine Oil Pressure.................... .................... 30

Engine Oil Pan........................ ........................ 31

Crankcase Breather.................... .................... 33

Water Temperature Regulator and Housing.. . 34

Water Pump.......................... .......................... 34

Cylinder Block......................... ........................ 35

Crankshaft........................... ........................... 35

Crankshaft Seals ...................... ...................... 36

Vibration Damper and Pulley............. ............. 37

Connecting Rod Bearing Journal.......... .......... 37

Main Bearing Journal................... ................... 38

Connecting Rod....................... ....................... 38

Piston and Rings ...................... ...................... 39

Piston Cooling Jet...................... ..................... 40

Accessory Drive (SAE “B” ).............. ............. 41

Index Section

Index................................ ............................... 61

This document is printed from SPI². Not for RESALE

![]()

4

UENR0675

Specifications Section

SpecificationsSection

i04928625

Fuel Injection Lines

i03519906

Engine Design

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel

spray may cause a fire hazard. Failure to follow

these inspection, maintenance and service in-

structions may cause personal injury or death.

Refer to Operation and Maintenance Manual,

“General Hazard Information and High Pressure Fuel

Lines” before adjustments and repairs are performed.

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

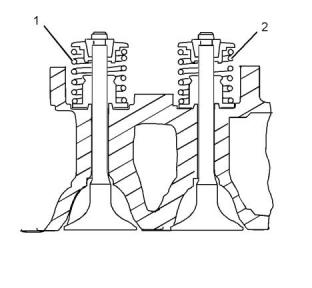

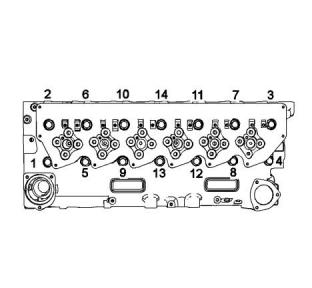

Illustration 1

g01284058

Cylinder and valve location

(A) Exhaust valve

(B) Inlet valve

Ensure that all adjustments and repairs are

performed by authorized personnel that have had the

correct training.

Bore ............................................105 mm (4.133 inch)

Stroke .........................................135 mm (5.315 inch)

Displacement......................7.01 L (427.78 cubic inch)

Cylinder arrangement ........................................In-line

Type of combustion ..............................Direct injection

Compression ratio

Turbocharged charge cooled ....................16.5:1

Number of cylinders .................................................. 6

Valves per cylinder .................................................... 4

Firing order .............................................1, 5, 3, 6, 2, 4

When the crankshaft is viewed from the front of the

engine, the crankshaft rotates in the following

direction: .....................................................Clockwise

When the camshaft is viewed from the front of the

engine, the camshaft rotates in the following direction:

.....................................................................Clockwise

The front of the engine is opposite the flywheel end.

The left side and the right side of the engine are

viewed from the flywheel end. The No. 1 cylinder is

the front cylinder.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

5

Specifications Section

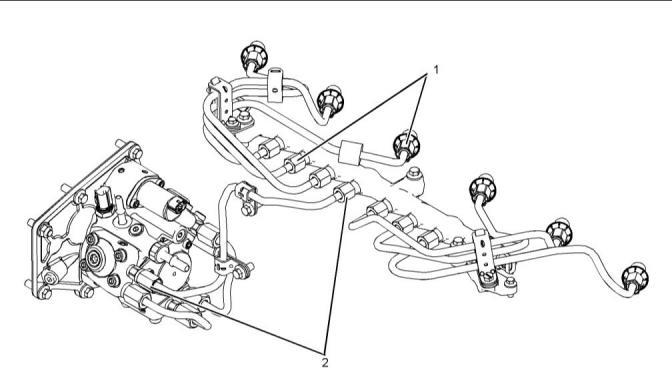

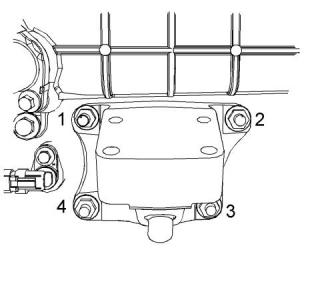

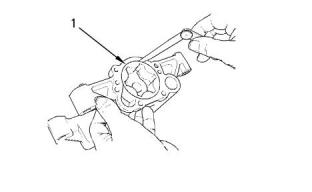

Illustration 2

g02293673

Typical example

(1) (2) Tighten the nuts on the high-pressure fuel lines

to the following torque.........................55 N·m (41 lb ft)

i04085749

Fuel Injection Pump

Note: The timing of the fuel injection pump will need

to be checked by trained personnel. In order to check

the timing of the fuel injection pump, refer to Systems

Operation, Testing and Adjusting, “Fuel Injection

Pump Timing - Check”.

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

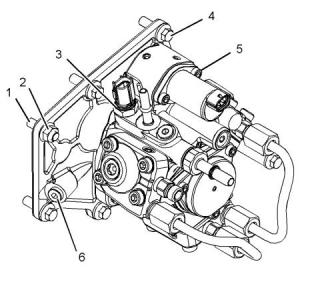

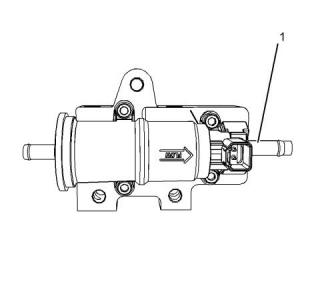

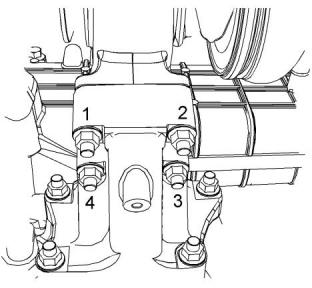

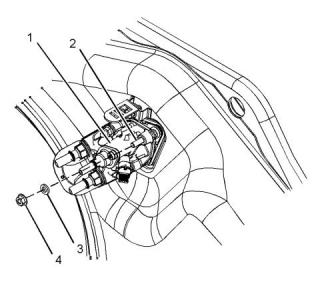

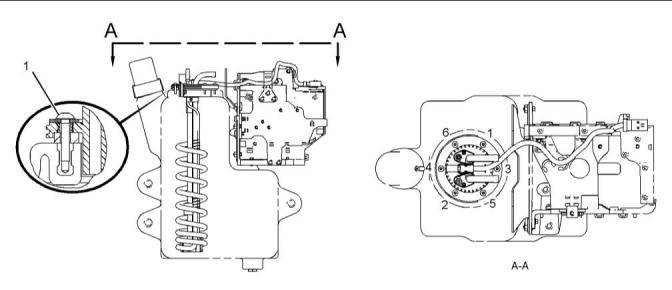

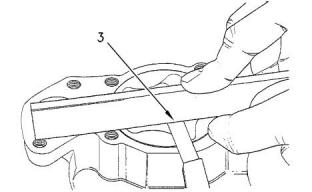

Illustration 3

g02293713

Typical example

(1) Tighten the studs to the following torque.....11 N·m

(97 lb in)

(2) Tighten the mounting nut to the following torque.

............................................................22 N·m (16 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

6

UENR0675

Specifications Section

(3) Tighten the fuel temperature sensor to the

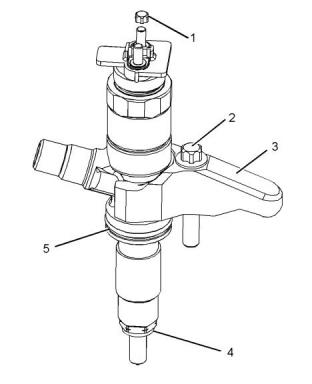

(2) Torque for the bolt in the clamp for the fuel

following torque...................................22 N·m (16 lb ft)

injection nozzle................................21 N·m (15.5 lb ft)

(4) Tighten the setscrews to the following torque.

............................................................22 N·m (16 lb ft)

i05449450

Fuel Transfer Pump

(Electric Transfer Pump)

(5) Tighten the screws for the suction control valve to

the following torque..............................9 N·m (80 lb in)

(6) Tighten the screw to the following torque.

............................................................14 N·m (10 lb ft)

i03631793

Fuel Injectors

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

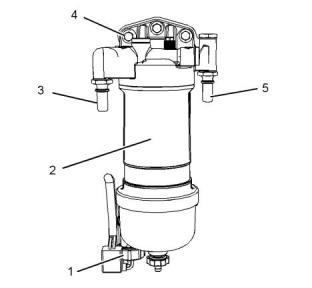

Illustration 5

g02291814

Typical example

(1) Tighten the connection to the following torque.

............................................................20 N·m (15 lb ft)

Illustration 4

g01862457

Typical example

(3) Clamp

(4) Washer

(5) O ring seal

Illustration 6

g02291815

(1) Torque for the nuts..........................2 N·m (18 lb in)

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

7

Specifications Section

(2) (3) Tighten the bolts to the following torque.

............................................................22 N·m (16 lb ft)

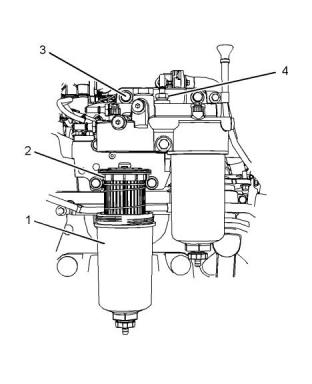

i05365831

Fuel Filter Base

(Single Secondary Fuel Filter

Base)

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

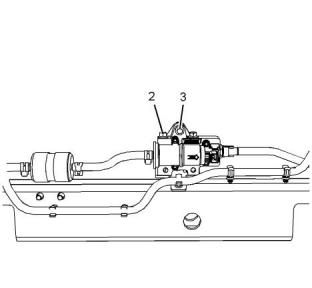

Illustration 8

g03396250

If necessary, install a new fuel filter (2) to canister (1).

Refer to Operation and Maintenance Manual, “Fuel

System Secondary Filter - Replace” for the correct

procedure.

Typical example

(5) Tighten the screw to the following torque.

..........................................................2.5 N·m (22 lb in)

i05371617

Fuel Filter Base

(Twin Secondary Fuel Filter

Base)

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

If necessary, install a new fuel filter (2) to canister (1).

Refer to Operation and Maintenance Manual, “Fuel

System Secondary Filter - Replace” for the correct

procedure.

Illustration 7

g02516539

Typical example

(3) Tighten the bolts to the following torque......44 N·m

(33 lb ft)

(4) Tighten the bolt to the following torque. ......17 N·m

(13 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

8

UENR0675

Specifications Section

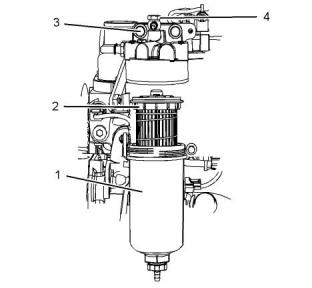

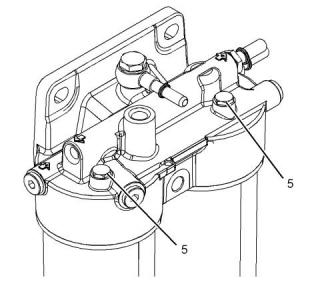

i04916708

Fuel Filter Base

(Primary Fuel Filter Base)

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

If necessary, install a new fuel filter element to

canister (2). Refer to Operation and Maintenance

Manual, “Fuel System Primary Filter (Water

Separator) Element - Replace” for the correct

procedure.

Illustration 9

g02518537

Typical example

(3) Tighten the bolts to the following torque......44 N·m

(33 lb ft)

(4) Tighten the bolt to the following torque. ......17 N·m

(13 lb ft)

Illustration 11

g03084516

Typical example

Tighten water in fuel switch (1) hand tight.

(3) Tighten the connection to the following torque.

............................................................17 N·m (13 lb ft)

(4) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

(5) Tighten the connection to the following torque.

............................................................17 N·m (13 lb ft)

Illustration 10

g03398925

Typical example

(5) Tighten the screws to the following torque.

..........................................................2.5 N·m (22 lb in)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

9

Specifications Section

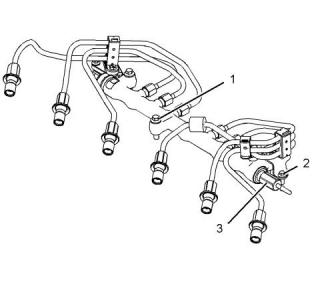

i04084390

Fuel Manifold (Rail)

Refer to Operation and Maintenance Manual,

“General Hazard Information and High Pressure Fuel

Lines” before adjustments and repairs are performed.

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

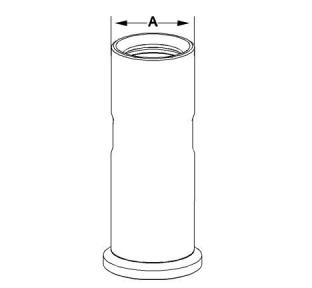

Illustration 13

g01866794

Typical example

(A) Diameter of the lifter body....21.938 to 21.963 mm

(0.86370 to 0.86468 inch)

Bore diameter in the cylinder block

.........22.000 to 22.032 mm (0.86614 to 0.86740 inch)

Clearance

Clearance of the lifter..............0.037 to 0.094 mm

(0.00146 to 0.00370 inch)

i03519944

Rocker Shaft

Illustration 12

g02293653

Typical example

(1) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

(2) Tighten the bolts to the following torque......10 N·m

(89 lb in)

(3) Tighten the fuel pressure relief valve to the

following torque...................................30 N·m (22 lb ft)

Note: The fuel pressure relief valve (3) should be

tightened an additional 24 degrees.

i03537811

Lifter Group

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

10

UENR0675

Specifications Section

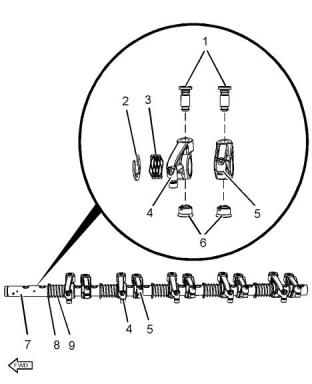

(9) Spring

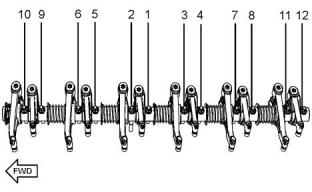

Illustration 15

g01850497

Tightening sequence

Tighten the fasteners in the sequence that is in

illustration 15 . Tighten the fasteners to the following

torque..................................................35 N·m (26 lb ft)

Illustration 14

g02113434

Typical example

(1) Tighten the threaded inserts to the following

torque..................................................30 N·m (22 lb ft)

(2) Retaining clip

(3) Spring

(4) Inlet rocker arm

Diameter of the rocker arm bore

......25.013 to 25.051 mm (0.9848 to 0.9863 inch)

(5) Exhaust rocker arm

Diameter of the rocker arm bore

......25.013 to 25.051 mm (0.9848 to 0.9863 inch)

Clearance

Maximum clearance of both the rocker arm

bores. ..............................0.089 mm (0.0035 inch)

The service limit for both rocker arm bores

..........................................0.17 mm (0.0067 inch)

(6) Guide

(7) Rocker shaft

Diameter of the rocker shaft

............................................24.962 to 24.987 mm

(0.98275 to 0.98374 inch)

(8) Retaining clip

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

UENR0675

11

Specifications Section

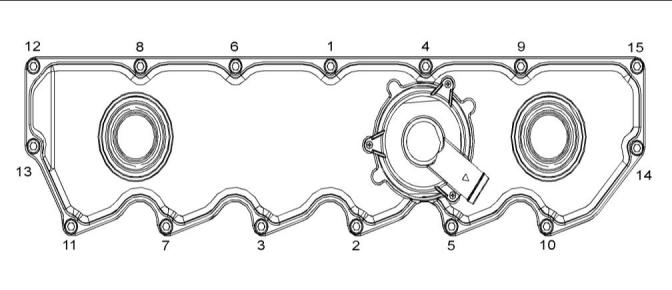

i03532881

Valve Mechanism Cover

Illustration 16

g01861234

Typical example

Tighten the bolts for the valve mechanism cover in

the sequence that is shown in illustration 16 . Torque

for the bolts..........................................9 N·m (80 lb in)

i03538600

Cylinder Head Valves

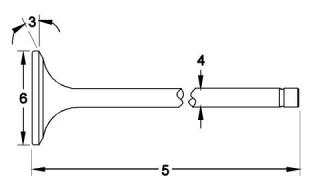

Illustration 17

g01927355

Typical example

(1) Exhaust valve spring

(2) Inlet valve spring

When the valve springs are replaced the valve

springs must be replaced in pairs.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

12

UENR0675

Specifications Section

Refer to table 1 and table 2 for information on the

length of the valve spring and the load of the valve

spring.

Clearance

Maximum clearance of the exhaust valve stem

Table 1

......................................0.075 mm (0.00295 inch)

The service limit for the exhaust valve stem

........................................0.10 mm (0.00394 inch)

The load for the inlet valve

spring

The length of the inlet valve

spring

161.5 to 178.5 N

(36.30682 to 40.12859 lb)

31.5 mm (1.2402 inch)

(5) Length of valve

Inlet valve.............................109.82 to 110.27 mm

(4.32361 to 4.34133 inch)

337.9 to 373.5 N

(75.96330 to 83.96654 lb)

21.5 mm (0.84646 inch)

Exhaust valve.................. 109.853 to 110.303 mm

(4.32491 to 4.34263 inch)

Note: The free length for the inlet valve spring is

40.65 mm (1.60039 inch).

(6) Valve head

Table 2

Diameter of inlet valve head ...................... 35 mm

(1.37795 inch)

The load for the exhaust valve

spring

The length of the exhaust valve

spring

Diameter of exhaust valve head ................ 33 mm

(1.2992 inch)

285 to 315 N

(64.07085 to 70.81515 lb)

31.5 mm (1.2402 inch)

408.5 to 451.5 N

(91.83488 to 101.50172 lb)

22.3 mm (0.87795 inch)

i04314230

Cylinder Head

Note: The free length for the exhaust valve spring is

52.73 mm (2.07598 inch).

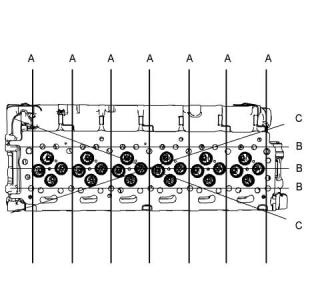

Illustration 18

g01927357

Typical example

(3) Valve face angle

Inlet .....................................................30 degrees

Exhaust ..............................................45 degrees

(4) Valve stem diameter

Illustration 19

g01852017

Inlet....6.970 to 6.985 mm (0.2744 to 0.2750 inch)

Exhaust...................................6.945 to 6.960 mm

(0.2734 to 0.2740 inch)

Typical example

Lubricate the threads and the underside of the head

bolts with clean engine oil.

Clearance

Tighten the bolts in the sequence that is shown in

illustration 19 . Torque for the bolts............50 N·m

(37 lb ft)

Tighten the bolts again to the following torque.

...................................................100N·m (74 lb ft)

Maximum clearance of the inlet valve stem

..........................................0.05 mm (0.0020 inch)

The service limit for the inlet valve stem

..........................................0.08 mm (0.0031 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

UENR0675

13

Specifications Section

Tighten the head bolts to the additional amount.

..........................................................225 degrees

Minimum thickness of cylinder head ...........150.8 mm

(5.93700 inch)

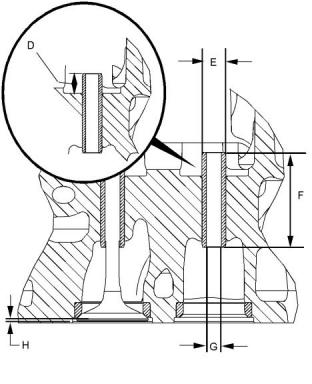

Illustration 20

g01854993

Typical example

Illustration 21

g02328933

Typical example

Note: The maximum distortion of the cylinder head is

given in table 3 .

(D) Valve guide height from the top of the valve guide

to the valve spring seat...................10.75 to 11.25 mm

(0.42323 to 0.44291 inch)

Table 3

Maximum Permissible

Dimension

Distortion

(E) Outside diameter of the valve guides

......... 11.029 to 11.040 mm (0.43421 to 0.43464 inch)

Width (A)

Length (B)

0.03 mm (0.0012 inch)

0.05 mm (0.0020 inch)

0.05 mm (0.020 inch)

(F) Length of the valve guides.......43.75 to 44.25 mm

(1.72244 to 1.74212 inch)

Diagonal Line (C)

(G) Internal diameter of the valve guides

.............7.007 to 7.020 mm (0.27587 to 0.27638 inch)

(H) Valve depths

Inlet....0.905 to 1.163 mm (0.0356 to 0.0458 inch)

The service limit for the depth of the inlet valve

.......................................... 1.41 mm (0.0555 inch)

Exhaust...................................0.876 to 1.131 mm

(0.0345 to 0.0445 inch)

The service limit for the exhaust valve depth

.......................................... 1.38 mm (0.0543 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

14

UENR0675

Specifications Section

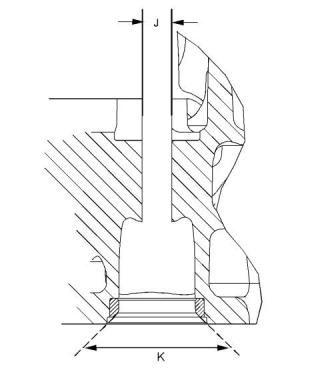

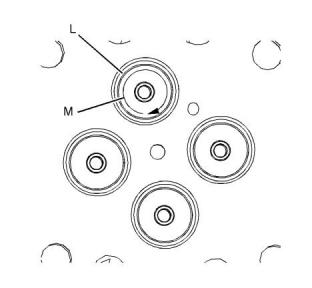

(L) Seat surface finish .........................Ra 0.8 microns

(M) Concentricity of valve seat to valve guide parent

bore Maximum Total Indicated Reading (TIR)

...............................................0.08 mm (0.00315 inch)

i05365854

Turbocharger

(Series Turbochargers)

Note: For the correct procedure to install the

turbochargers, refer to Disassembly and Assembly,

“Turbocharger - Install”.

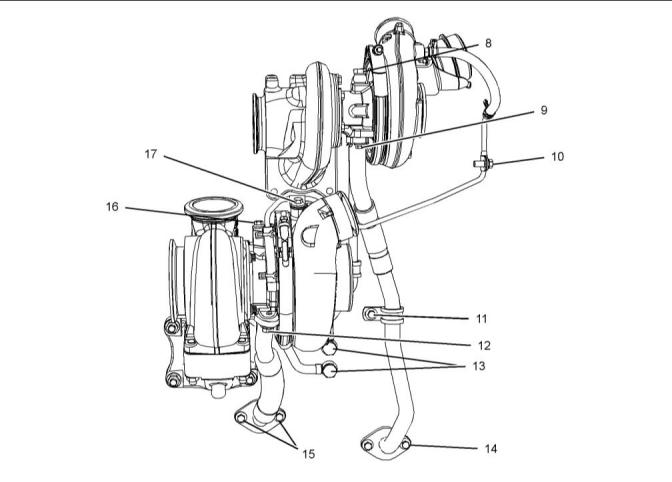

Illustration 22

g02474819

Typical example

(J) Diameter of the parent bore in the cylinder head

......... 11.000 to 11.022 mm (0.43307 to 0.43394 inch)

(K) Seat angle

Inlet .............................................. 119.15 degrees

Exhaust .........................................89.15 degrees

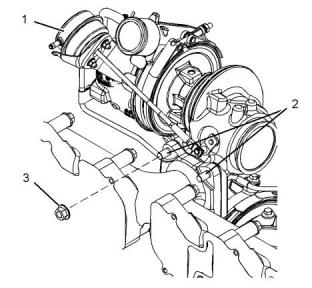

Illustration 24

g03097997

Typical example

(1) Actuator

The test pressure for the wastegate actuator

...............................................................60 kPa (9 psi)

The movement for the rod actuator ....................1 mm

(0.0394 inch)

(2) Tighten the studs to the following torque.

............................................................18 N·m (13 lb ft)

(3) Tighten the nuts to the following torque. .....44 N·m

(32 lb ft)

Illustration 23

g02475018

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

15

Specifications Section

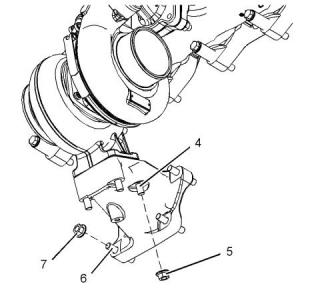

Illustration 25

g03098036

Illustration 27

g02352719

Typical example

Tightening sequence for the nuts that secure the

turbocharger to the bracket

(4) (6) Tighten the studs to the following torque.

............................................................18 N·m (13 lb ft)

(5) (7) Tighten the nuts to the following torque.

............................................................44 N·m (32 lb ft)

Illustration 26

g03396277

Tightening sequence for the nuts that secure the

bracket to the cylinder block

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

16

UENR0675

Specifications Section

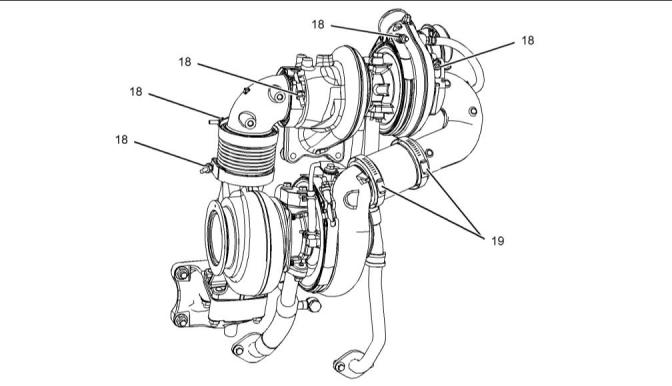

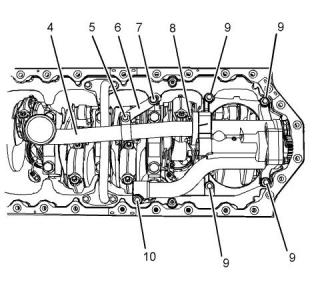

Illustration 28

g03098058

Typical example

(8) Tighten the bolt to the following torque. ......15 N·m

(11 lb ft)

(9) Tighten the bolts to the following torque........9 N·m

(80 lb in)

(10) (11) (17) Tighten the bolt to the following torque.

............................................................18 N·m (13 lb ft)

(12) (14) (15) (16) Tighten the bolts to the following

torque..................................................22 N·m (16 lb ft)

(13) Tighten the bolt to the following torque. ....33 N·m

(24 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

UENR0675

17

Specifications Section

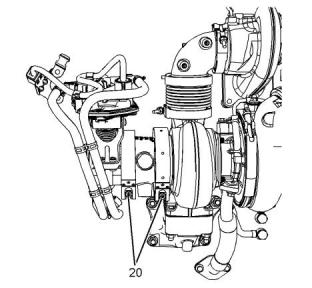

Illustration 29

g03120317

i04928651

Typical example

(18) Tighten the band clamps for the turbochargers to

the following torque..........................12 N·m (106 lb in)

Turbocharger

(Single Turbocharger)

(19) Tighten the band clamps for the ducts to the

following torque....................................6 N·m (53 lb in)

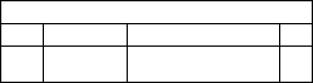

Illustration 30

g03120696

Typical example

(20) Tighten the band clamps for the turbochargers to

the following torque..........................12 N·m (106 lb in)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

18

UENR0675

Specifications Section

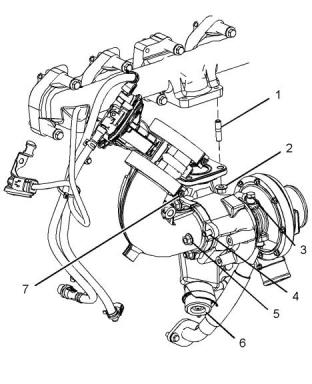

Illustration 32

g03097926

Typical example

(8) Tighten the bolts to the following torque........9 N·m

(80 lb in)

(9) Tighten the bolt to the following torque. ......33 N·m

(24 lb ft)

Illustration 31

g03097898

Typical example

(10) Tighten the bolt to the following torque. ....22 N·m

(16 lb ft)

(1) Tighten the studs to the following torque.

............................................................18 N·m (13 lb ft)

(2) Tighten the nuts to the following torque. .....44 N·m

(32 lb ft)

i05380879

Injector (Diesel Exhaust Fluid)

(3) Tighten the bolt to the following torque. ......15 N·m

(11 lb ft)

(4) Tighten the studs to the following torque.

............................................................18 N·m (13 lb ft)

Table 4

Required Tools

(5) Tighten the nuts to the following torque. .....44 N·m

(32 lb ft)

Tool

Part Number

Part Description

Qty

Bostik Pure Nickel

Anti-Seize Compound

(6) Actuator

A

-

1

The test pressure for the wastegate actuator

...............................................................60 kPa (9 psi)

The movement for the rod actuator .................... 1 mm

(0.0394 inch)

(7) Tighten the band clamps to the following torque.

.........................................................12 N·m (106 lb in)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

UENR0675

19

Specifications Section

Illustration 33

g03404738

Typical example

(1) Injector (Diesel Exhaust Fluid)

(2) Stud

(3) Washer

Lightly lubricate the thread of the studs (2) and nuts

(4) with Tooling (A) before installation.

(2) Tighten the studs to the following torque.......5 N·m

(44 lb in)

(4) Tighten the nuts to an initial torque. ..............5 N·m

(44 lb in)

(4) Tighten the nuts to a final torque...................5 N·m

(44 lb in)

Tighten the nuts to the additional amount. ..............90

degrees

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

20

UENR0675

Specifications Section

i05380938

Manifold (Diesel Exhaust Fluid)

Illustration 34

g03404759

Typical example

(1) Tighten the screws in the tightening sequence as

shown in illustration 34 to an initial torque.........5 N·m

(44 lb in)

(1) Tighten the screws in the tightening sequence as

shown in illustration 34 to a final torque.............5 N·m

(44 lb in)

i05380903

Diesel Exhaust Fluid Tank

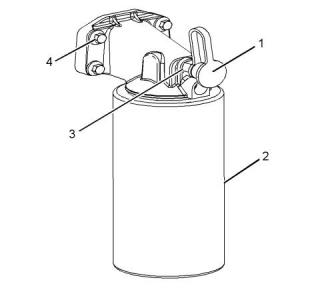

Illustration 35

g03404743

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

UENR0675

21

Specifications Section

(1) Tighten the cap adapter or hose adapter to the

following torque...................................15 N·m (11 lb ft)

Tighten the self-taping screws to the following torque.

..........................................................2.8 N·m (25 lb in)

(2) Tighten the plug to the following torque. .....11 N·m

(97 lb in)

Note: The Original Equipment Manufacturer (OEM)

may supply the Diesel Exhaust Fluid (DEF) tank.

Refer to the OEM for more information if the DEF tank

has been supplied by the OEM.

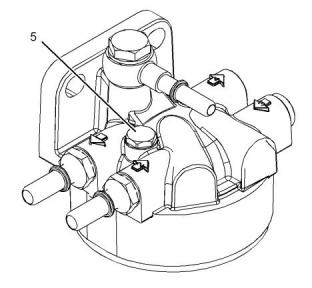

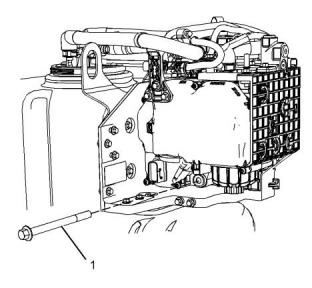

i05380925

Diesel Exhaust Fluid Pump

Illustration 37

g01946893

Typical example

(1) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

Illustration 36

g03404752

Typical example

(1) Tighten the bolts to the following torque......19 N·m

(14 lb ft)

Note: The maximum wrench speed is 60 rpm.

i04928588

Exhaust Gas Valve (NRS)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

22

UENR0675

Specifications Section

Illustration 38

g02295533

Typical example

(2) Tighten the bolts to the following torque......18 N·m

(13 lb ft)

(3) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

(4) Tighten the clamps to the following torque.

...........................................................11 N·m (97 lb in)

(5) Tighten the bolt to the following torque. ......18 N·m

(13 lb ft)

Illustration 39

g03097576

Typical example

(6) Tighten the bolt to the following torque. ......15 N·m

(11 lb ft)

(7) (8) Tighten the fasteners to the following torque.

............................................................18 N·m (13 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

UENR0675

23

Specifications Section

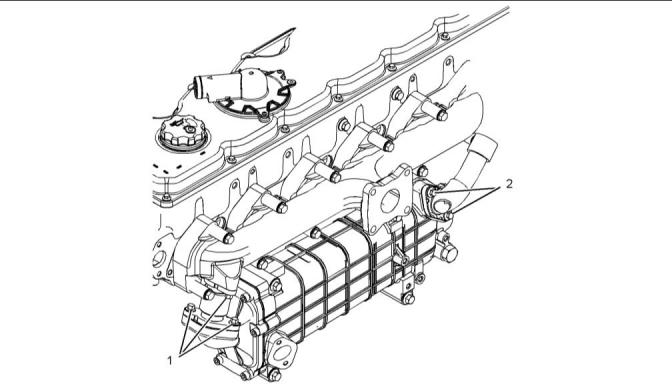

i04928620

Exhaust Cooler (NRS)

Note: When the pipes for the exhaust cooler are

removed or installed, care must be taken so that the

pipes are not bent or damaged.

Illustration 40

g02295833

Typical example

(1) (2) Tighten the setscrews to the following torque.

............................................................22 N·m (16 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

24

UENR0675

Specifications Section

Illustration 41

g02295755

Typical example

(3) (6) (7) (9) Tighten the setscrews to the following

torque..................................................22 N·m (16 lb ft)

(4) Tighten the setscrews to, the following torque.

............................................................18 N·m (13 lb ft)

(5) (8) Tighten the setscrews to the following torque.

............................................................44 N·m (32 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

UENR0675

25

Specifications Section

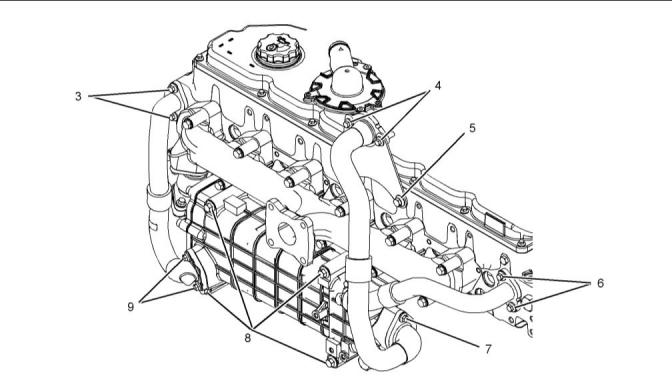

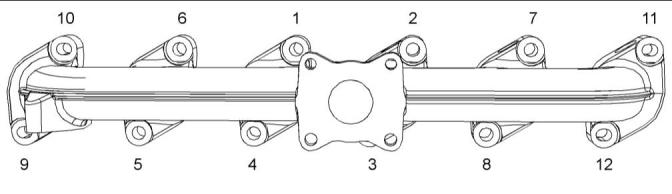

i04364975

Exhaust Manifold

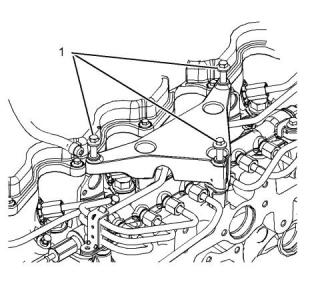

Illustration 42

g02330776

Typical example

Tighten the exhaust manifold bolts in the sequence

that is shown in illustration 42 to the following torque.

............................................................44 N·m (32 lb ft)

To measure the flatness of the exhaust manifold,

follow step 1 to step 4.

1. Remove all bolts and spacers from the exhaust

manifold.

2. Install two spacers and bolts into holes eleven and

twelve of port one of the exhaust manifold.

3. Tighten the bolts to a torque of 44 N·m (32 lb ft).

4. Use a suitable feeler gauge to measure the gap

that is between port six (holes nine and ten) of the

exhaust manifold and the cylinder head.

The maximum amount that the gap should be is

.................................................1.4 mm (0.05512 inch)

For the correct procedures to remove and install the

exhaust manifold, refer to Disassembly and

Assembly.

This document is printed from SPI². Not for RESALE

![]()

![]()

26

UENR0675

Specifications Section

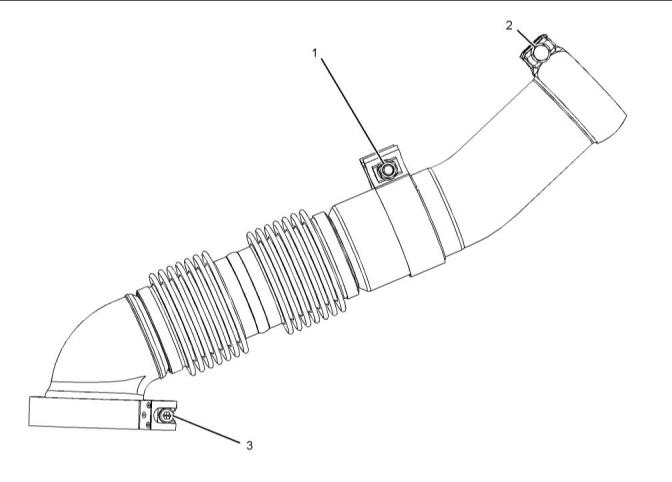

i05365841

Flexible Exhaust Pipe

Illustration 43

g03396256

i05452413

Typical example

(1) Tighten the clamp to the following torque.

............................................................55 N·m (41 lb ft)

Camshaft

(2) Tighten the clamp to the following torque.

............................................................35 N·m (26 lb ft)

(3) Tighten the clamp to the following torque.

.........................................................12 N·m (106 lb in)

Refer to Disassembly and Assembly for the correct

procedure to install the flexible exhaust pipe.

This document is printed from SPI². Not for RESALE

![]()

![]()

UENR0675

27

Specifications Section

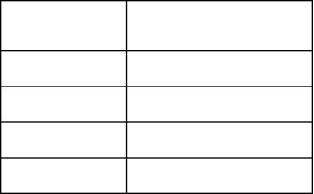

Table 5

Camshaft Journals from

the Front End of the

Engine

Standard Diameter

1

Front

50.711 to 50.737 mm

(1.9965 to 1.9975 inch)

50.457 to 50.483 mm

(1.9865 to 1.9875 inch)

2

3

50.203 to 50.229 mm

(1.9765 to 1.9775 inch)

4

Rear

49.949 to 49.975 mm

(1.9665 to 1.9675 inch)

Maximum wear on the camshaft journals...... 0.05 mm

(0.0021 inch)

Check the camshaft lobes for visible damage. If a

new camshaft is installed, you must install new lifters.

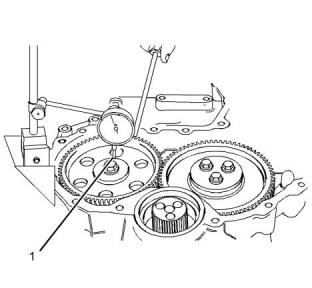

Illustration 44

g01927854

Checking the end play of the camshaft

(1) End play of a camshaft.............0.106 to 0.558 mm

(0.00417 to 0.02197 inch)

Maximum permissible end play of a worn camshaft

.................................................0.62 mm (0.0244 inch)

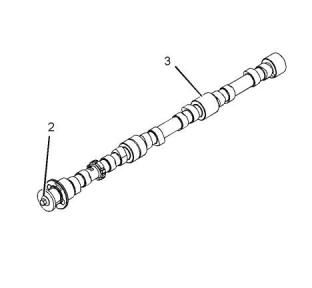

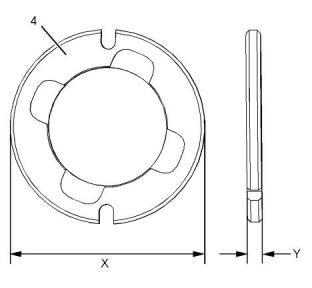

Illustration 46

g02474757

Typical example

(4) Camshaft thrust washer

Outer diameter (X) ..............72.949 to 73.000 mm

(2.872 to 2.874 inch)

Thickness (Y) ......................... 5.486 to 5.537 mm

(0.21598 to 0.21799 inch)

Illustration 45

g03442257

Typical example

i03530782

Camshaft Bearings

(2) Bolt

Torque for the 8.8 graded bolt......95 N·m (70 lb ft)

Torque for the 10.9 graded bolt................120 N·m

(89 lb ft)

(3) The diameters of the camshaft journals are given

in the following tables.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

28

UENR0675

Specifications Section

Torque for the engine oil filter....12 N·m (106 lb in)

(3) Engine oil sampling valve

Torque for the engine oil sampling valve (if

equipped)..................................12 N·m (106 lb in)

Torque for the plug (if equipped)......12 N·m (106 lb in)

(4) Setscrew

Torque for the setscrews that retain the oil filter

base .............................................22 N·m (16 lb ft)

i04916915

Engine Oil Cooler

Illustration 47

g01859293

Engine Oil Cooler with a Low

Mounted Filter Base

Typical example

(1) The diameter of the installed camshaft bearing

.............50.787 to 50.848 mm (1.9995 to 2.0019 inch)

i03551117

Engine Oil Filter Base

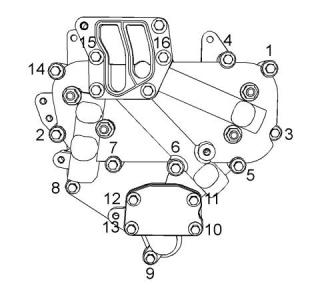

Illustration 49

g03084977

Typical example

Setscrews

Tighten the setscrews in the sequence that is in

illustration 49 to the following torque.........22 N·m

(16 lb ft)

Illustration 48

g01877935

Typical example

(1) Dust cap

(2) Engine oil filter

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

29

Specifications Section

Engine Oil Cooler with a High

Mounted Filter Base

Illustration 51

g00938064

(1) Clearance of the outer rotor to the body

.................0.050 to 0.330 mm (0.0020 to 0.0130 inch)

Illustration 50

g01854213

Typical example

Setscrews

Tighten the setscrews in the sequence that is in

illustration 50 to the following torque.........22 N·m

(16 lb ft)

Illustration 52

g00938061

i04363634

Checking the clearance

Engine Oil Pump

(2) Service limit of inner rotor to outer rotor

.................0.080 to 0.250 mm (0.0031 to 0.0098 inch)

Type ...............................Gear-driven differential rotor

Number of lobes

Inner rotor ........................................................... 6

Outer rotor ..........................................................7

Illustration 53

g00938799

Checking the end play

(3) End play of rotor assembly

Inner rotor................................0.050 to 0.180 mm

(0.0020 to 0.0071 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

30

UENR0675

Specifications Section

Outer rotor............................... 0.050 to 0.180 mm

(0.0020 to 0.0071 inch)

Illustration 54

g02293754

Typical example

(4) Suction Pipe

(6) Bracket for the Suction Pipe

(5) (8) (9) (10) Tighten the bolts to the following

torque..................................................22 N·m (16 lb ft)

(7) Tighten the bolt to the following torque. ......44 N·m

(32 lb ft)

i03540441

Engine Oil Pressure

The minimum oil pressure at a maximum engine

speed of 2200 rpm and at normal operating

temperature is the following value.....315 kPa (45 psi)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

UENR0675

31

Specifications Section

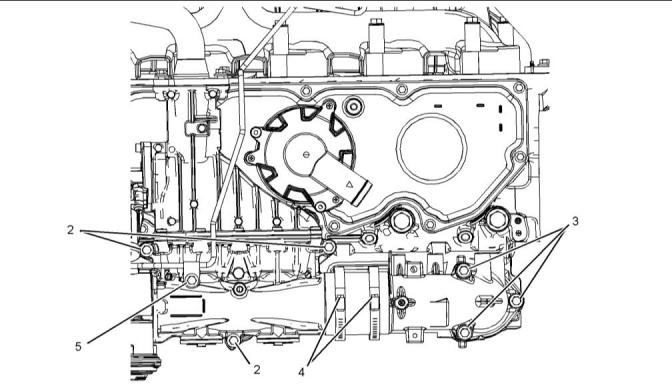

i04129089

Engine Oil Pan

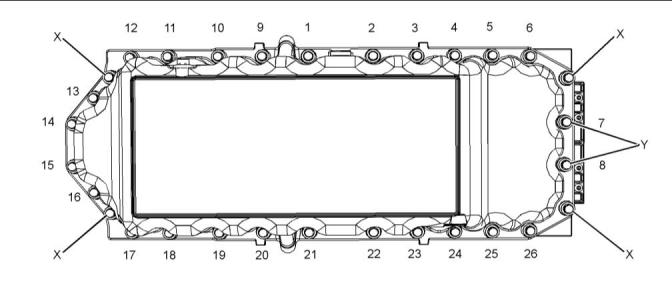

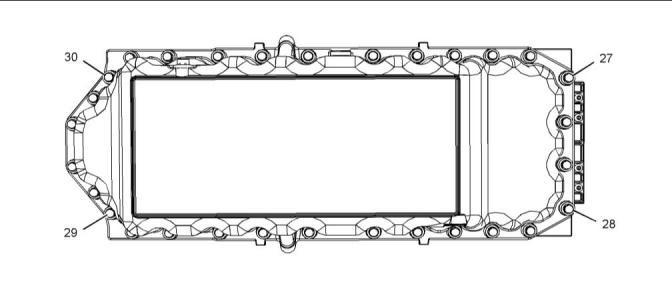

Illustration 55

g01856874

(X) Guide studs

(Y) Short fastener

Tighten the fasteners in the sequence that is shown in

illustration 55 . Torque for the fasteners ...........22 N·m

(16 lb ft)

This document is printed from SPI². Not for RESALE

![]()

![]()

32

UENR0675

Specifications Section

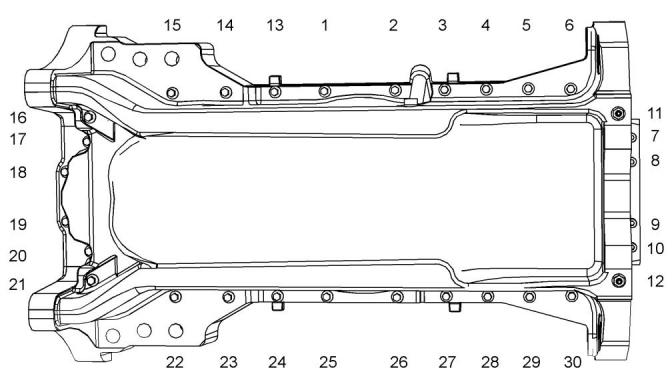

Illustration 56

g01857014

Remove the guide studs. Install the fasteners (27),

(28), (29) and (30).

Tighten the fastener in the sequence that is shown in

illustration 56 . Torque for the fasteners ...........22 N·m

(16 lb ft)

Tighten the oil drain plug to the following torque.

............................................................34 N·m (25 lb ft)

Tighten the oil level switch (if equipped) to the

following torque...................................34 N·m (25 lb ft)

Refer to the Disassembly and Assembly, “Engine Oil

Pan” for the correct procedure to install the engine oil

pan.

The Cast Iron Oil Pan

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

UENR0675

33

Specifications Section

Illustration 57

g01397669

Tightening sequence

Tighten the fasteners in the sequence that is shown in

illustration 57 to the following torque. ..............22 N·m

(16 lb ft)

Tighten the oil drain plug to the following torque.

............................................................34 N·m (25 lb ft)

Tighten the oil level switch (if equipped) to the

following torque...................................34 N·m (25 lb ft)

i04085789

Crankcase Breather

Illustration 58

g02295333

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

34

UENR0675

Specifications Section

(1) (2) (3) Tighten the setscrews to the following

torque..................................................22 N·m (16 lb ft)

(4) Tighten the setscrews to the following torque.

............................................................44 N·m (32 lb ft)

Note: If a hexagonal pillar spacer is required, install

the spacer to the engine oil cooler. Tighten the spacer

to a torque of 22 N·m (16 lb ft).

i03520180

Water Temperature Regulator

and Housing

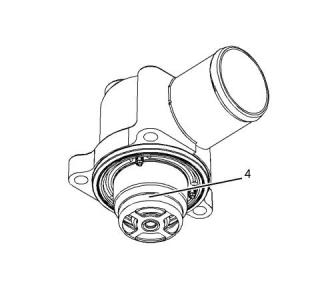

Illustration 60

g01854133

(4) Water temperature regulator

Opening temperature..........................80° to 84°C

(151° to 176°F)

Maximum open length of 11 mm (0.43307 inch)

is achieved at the following temperature. .... 94° C

(201° F)

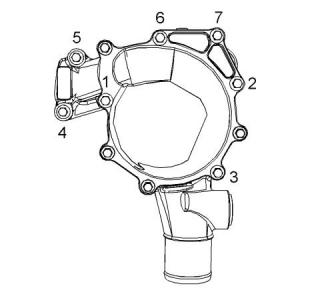

i03520301

Water Pump

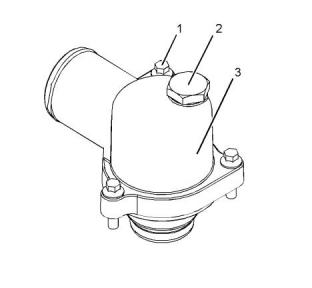

Illustration 59

g01853873

Typical example

Water temperature regulator housing

(1) Torque for the bolts that fasten the housing to the

cylinder head ......................................22 N·m (16 lb ft)

(2) Torque for the vent plug........... 22 N·m (16.22 lb ft)

Illustration 61

g01850741

Tightening sequence

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR0675

35

Specifications Section

Tighten the setscrews in the numerical sequence that

is shown in illustration 61 to the following torque.

............................................................22 N·m (16 lb ft)

(5) Main bearing cap bolts

Use the following procedure in order to install the

main bearing cap bolts:

1. Apply clean engine oil to the threads of the main

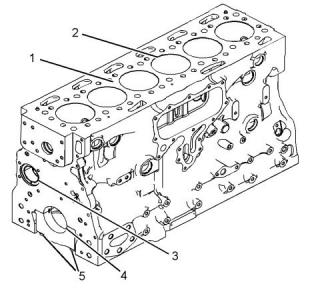

i04117792

bearing cap bolts.

Cylinder Block

2. Put the main bearing caps in the correct position

that is indicated by a number on the top of the main

bearing cap. Install the main bearing caps with the

locating tabs in correct alignment with the recess in

the cylinder block.

3. Evenly tighten the main bearing cap bolts.

Torque for the main bearing cap bolts. .............80 N·m

(59 lb ft)

4. After torquing the bolts for the main bearing caps,

the bolts must be rotated for an additional 90

degrees.

Note: Ensure that the crankshaft can rotate freely.

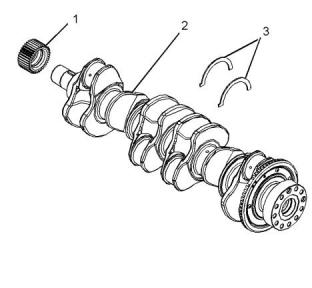

i04029133

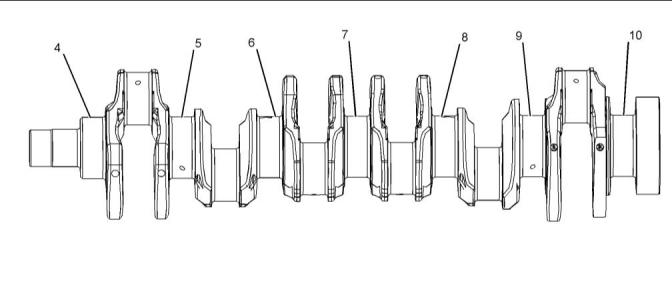

Crankshaft

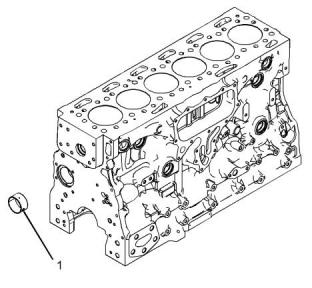

Illustration 62

g01855114

Cylinder block

(1) Cylinder block

(2) Cylinder bore....................105.000 to 105.025 mm

(4.1338 to 4.1348 inch)

(3) Camshaft bearings

Diameter of the bushing in the cylinder block for

the number 1 camshaft bearing

......55.563 to 55.593 mm (2.1875 to 2.1887 inch)

Diameter of the bore in the cylinder block for the

number 2 camshaft journal

......50.546 to 50.597 mm (1.9900 to 1.9920 inch)

Diameter of the bore in the cylinder block for the

number 3 camshaft journal

......50.292 to 50.343 mm (1.9800 to 1.9820 inch)

Diameter of the bore in the cylinder block for the

number 4 camshaft journal

Illustration 63

g01862538

Typical example

(1) Crankshaft gear

(2) Crankshaft

......50.038 to 50.089 mm (1.9700 to 1.9720 inch)

(3) Crankshaft thrust washers

(4) Main bearings

Maximum permissible temperature of the gear for

installation on the crankshaft..............180 °C (356 °F)

Bore in the cylinder block for the main bearings

......88.246 to 88.272 mm (3.4742 to 3.4753 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

36

UENR0675

Specifications Section

The end play of a new crankshaft........ 0.1 to 0.41 mm

(0.00394 to 0.01614 inch)

Standard thickness of thrust washer

.....................2.69 to 2.75 mm (0.1059 to 0.1083 inch)

Oversize thickness of thrust washer

......................2.89 to 2.95 mm (0.1138 to 0.1161 inch)

Illustration 64

g01869273

i03520221

(4) Journal 1

(5) Journal 2

(6) Journal 3

(7) Journal 4

(8) Journal 5

(9) Journal 6

(10) Journal 7

Refer to Table 6 for the run out of the crankshaft

journals.

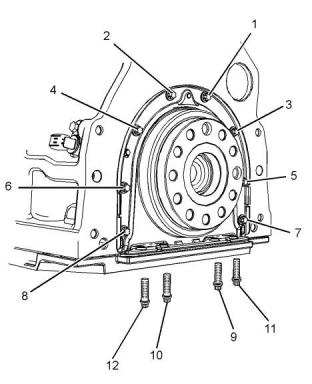

Crankshaft Seals

Table 6

Journal

Run Out of the Journals

(1)

Mounting

(2)

(3)

(4)

(5)

(6)

(7)

0.05 mm (0.0020 inch)

0.1 mm (0.0039 inch)

0.15 mm (0.0059 inch)

0.1 mm (0.0039 inch)

0.05 mm (0.0020 inch)

Mounting

You do not need to remove the engine oil pan in order

to install the oil seal.

Note: Some engines also have an oil seal that is

installed in the flywheel housing. Refer to

Specifications, “Flywheel Housing” for more

information.

Inspect the crankshaft for wear or for damage. For

more information regarding the servicing of the

crankshaft, contact the Global Technical Support

Center.

Refer to Specifications, “Connecting Rod Bearing

Journal” for more information on the connecting rod

bearing journals and connecting rod bearings.

Refer to Specifications, “Main Bearing Journal” for

information on the main bearing journals and for

information on the main bearings.

This document is printed from SPI². Not for RESALE

![]()

![]()

UENR0675

37

Specifications Section

The sequence for installationof the

rear oil seal

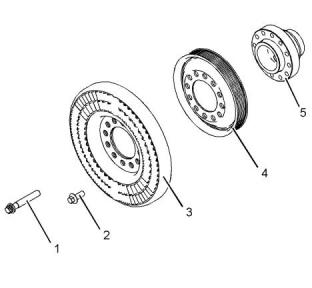

Illustration 66

g02282353

Typical example

(1) Tighten the setscrews for the adapter to the

following torque...................................40 N·m (30 lb ft)

The setscrews must be tightened through an angle of

120 degrees.

(2) Tighten the bolts for the damper and pulley to the

following torque.................................115 N·m (85 lb ft)

Illustration 65

g01863635

Typical example

(3) Vibration damper

(4) Crankshaft pulley

(5) Crankshaft adapter

(11) (12) Torque for the fasteners.......15 N·m (11 lb ft)

(1) (2) Torque for the fastener.............22 N·m (16 lb ft)

Loosen fastener (11) and (12) by one complete turn.

i05197127

Tighten the fasteners in the sequence that is in

illustration 65 . Torque for the fasteners ...........22 N·m

(16 lb ft)

Connecting Rod Bearing

Journal

The maximum out of concentricity between the

crankshaft flange and the outside diameter of the rear

seal for the crankshaft. ............0.4 mm (0.01575 inch)

The original size of the connecting rod bearing journal

on the crankshaft.......................71.970 to 71.990 mm

(2.83346 to 2.83425 inch)

i04067351

Vibration Damper and Pulley

Maximum permissible wear of a bearing journal on

the crankshaft when a new connecting rod is installed

.................................................0.04 mm (0.0016 inch)

Width of the connecting rod bearing journals on the

crankshaft..................................37.962 to 38.038 mm

(1.4946 to 1.4976 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

38

UENR0675

Specifications Section

Radius of the fillet of the connecting rod bearing

journals..........................................3.875 to 4.125 mm

(0.15256 to 0.16240 inch)

Clearance between the bearing shell and the main

bearing journals.............................0.036 to 0.094 mm

(0.00142 to 0.00370 inch)

Surface finish of connecting rod bearing journals

...........................................................Ra 0.25 microns

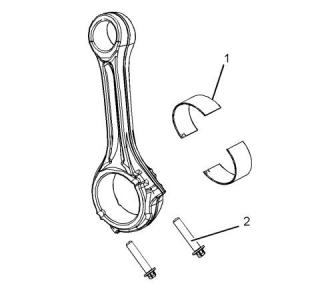

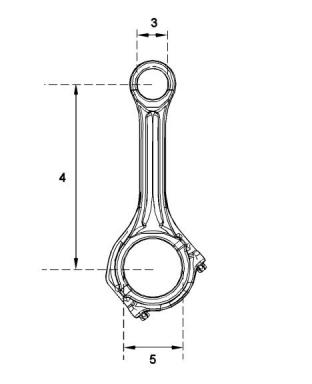

i04234795

Connecting Rod

Surface finish of radii ..........................Ra 0.4 microns

i05197134

Main Bearing Journal

The original size of the main bearing journal

.........83.980 to 84.000 mm (3.30629 to 3.30708 inch)

Maximum permissible wear of the main bearing

journals..................................0.040 mm (0.0016 inch)

Radius of the fillet of the main bearing journals

.............3.875 to 4.125 mm (0.15256 to 0.16240 inch)

Surface finish of bearing journals and crank pins

...........................................................Ra 0.25 microns

Surface finish of radii ..........................Ra 0.4 microns

Width of new main bearing journal where the thrust

washer is installed .....................35.235 to 35.165 mm

(1.3872 to 1.3844 inch)

Illustration 67

g01860862

Typical example

Width of new main bearing journal where the thrust

washer is not installed ...................35.25 to 35.15 mm

(1.38779 to 1.38386 inch)

(1) The bearing shell for the connecting rod

For the correct procedure to install the bearing shell

for the connecting rod, refer to Disassembly and

Assembly, “Pistons and Connecting Rods -

Assemble”.

The shell for the main bearings

The shells for the main bearings are available for

remachined journals which have the following

oversize dimensions.

Table 7

Thickness of Connecting Rod

Bearing at the Center

1.994 to 2.000 mm

(0.0785 to 0.0787 inch)

Oversize bearing shell ........0.25 mm (0.010 inch)

Oversize bearing shell ........0.50 mm (0.020 inch)

Oversize bearing shell ........0.76 mm (0.030 inch)

Thickness of Bearing Cap at

the Center

1.994 to 2.000 mm

(0.0785 to 0.0787 inch)

0.080 to 0.035 mm

(0.00315 to 0.00138 inch)

Bearing Clearance

Thickness at center of the shells of oversize bearing

shell 0.25 mm (0.010 inch) ...........2.226 to 2.232 mm

(0.08764 to 0.08787 inch)

Table 8

Oversize Connecting Rod Bearing

Thickness at center of the shells of oversize bearing

shell 0.50 mm (0.020 inch) ...........2.353 to 2.359 mm

(0.09264 to 0.09287 inch)

0.25 mm (0.010 inch)

0.51 mm (0.020 inch)

0.76 mm (0.030 inch)

Thickness at center of the shells of oversize bearing

shell 0.76 mm (0.030 inch) ...........2.480 to 2.486 mm

(0.09764 to 0.09787 inch)

Width of the main bearing shells ... 26.32 to 26.58 mm

(1.03622 to 1.04645 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

UENR0675

39

Specifications Section

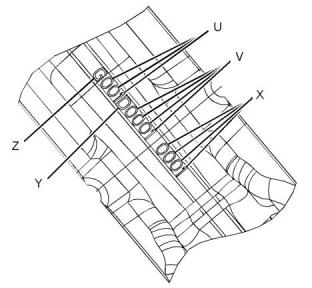

Illustration 68

g01950657

Typical example

(U) Day code

(V) Code for the connecting rod

(X) Code for the Connecting rod cap

(Y) Year code

(Z) Code for the grade of connecting rod

Illustration 69

g01860878

Note: The day code is from the first day in the year.

For example, “001” will be the first day of the

appropriate year.

Typical example

(3) Diameter of the finished bore for the piston pin

.............39.738 to 39.723 mm (1.5645 to 1.5639 inch)

The mating surfaces of the connecting rod are

produced by hydraulically fracturing the forged

connecting rod. Ensure that the correct cap for the

connecting rod is installed with the correct connecting

rod. Ensure that the serial numbers for both

components match.

(4) Distance between the parent bores

...............219.05 to 219.1 mm (8.6240 to 8.6260 inch)

(5) Diameter for the finished bore for the connecting

rod bearing.................................76.025 to 76.038 mm

(2.99310 to 2.99362 inch)

(2) Torque of the setscrews for the connecting rod

............................................................40 N·m (30 lb ft)

The connecting rod is color coded. The color code is

a reference for the length of the connecting rod. Refer

to table 9 for the length of connecting rod.

Tighten the setscrews for the connecting rod for an

additional 120 degrees. The setscrews for the

connecting rod (2) must be replaced after this

procedure.

Table 9

Specificationsfor the Connecting Rod

Note: Always tighten the connecting rod cap to the

connecting rod, when the assembly is out of the

engine. Tighten the assembly to the following torque

20 N·m (14 lb ft).

Length Of The Connect-

Grade Letter Color Code

ing Rod

161.107 to 161.140 mm

(6.3428 to 6.3441 inch)

B

Blue

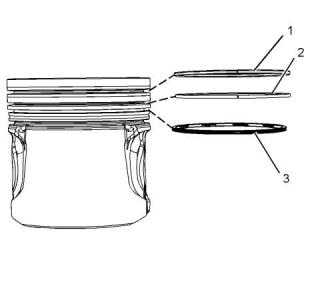

i04939374

Piston and Rings

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

40

UENR0675

Specifications Section

(3) The oil control ring

Width of oil control ring................2.79 to 3.00 mm

(0.10984 to 0.11811 inch)

The clearance between a new oil control ring and

the groove in a new piston..........0.05 to 0.10 mm

(0.00197 to 0.00394 inch)

Ring gap......................................0.30 to 0.55 mm

(0.0118 to 0.0216 inch)

Note: When you install a new oil control ring, make

sure that the word “TOP” is facing the top of the

piston. New oil control rings have a red identification

mark. The identification mark must be on the left of

the ring end gap when the top piston ring is installed

on an upright piston. The oil control ring is a two-

piece ring that is spring loaded. A pin is used in order

to hold both ends of the spring of the oil control ring in

position. The ends of the spring of the oil control ring

must be installed opposite the end gap of the oil

control ring.

Illustration 70

g03120776

Typical example

Note: Ensure that the ring end gaps of the piston

rings are spaced 120 degrees from each other.

(1) Top compression ring

Piston

The shape of the top compression ring

...............................................................Keystone

Note: An arrow which is marked on the piston crown

must be toward the front of the engine.

Ring gap......................................0.25 to 0.35 mm

(0.00984 to 0.01378 inch)

Piston height above cylinder block.... 0.55 to 0.20 mm

(0.02165 to 0.00787 inch)

Note: When you install a new top compression ring,

make sure that the word “TOP” is facing the top of

the piston. New top piston rings have a black

identification mark. The identification mark must be

on the left of the ring end gap when the top piston ring

is installed on an upright piston.

Width of top groove in the piston ...................Tapered

Width of second groove in new piston

.....................2.56 to 2.58 mm (0.1008 to 0.1016 inch)

Width of third groove in new piston.... 3.05 to 3.07 mm

(0.12008 to 0.12087 inch)

(2) Intermediate compression ring

The shape of the intermediate compression ring

...............Internal bevel in the bottom edge with a

tapered face

Piston pin

Diameter of a new piston pin

......39.694 to 39.700 mm (1.5628 to 1.5630 inch)

Width of intermediate compression ring

............2.47 to 2.495 mm (0.0972 to 0.0982 inch)

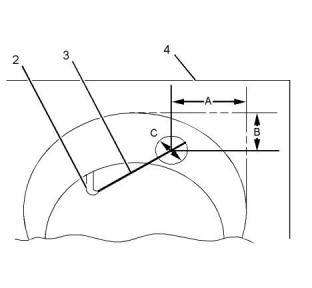

i03520280

The clearance between a new intermediate

compression ring and the piston groove in a new

piston........................................0.065 to 0.110 mm

(0.00256 to 0.00433 inch)

Piston Cooling Jet

Ring gap......................................0.65 to 0.85 mm

(0.0256 to 0.0335 inch)

Note: When you install a new intermediate

compression ring, make sure that the word “TOP” is

facing the top of the piston. New intermediate rings

have a blue identification mark. The identification

mark must be on the left of the ring end gap when the

top piston ring is installed on an upright piston.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

UENR0675

41

Specifications Section

3. The position of the rod (3) must be within

dimension (C). Dimension (C) is 10 mm

(0.39370 inch).

Note: Ensure that the rod (3) can not damage the

piston cooling jet when the alignment is checked. The

piston cooling jets can not be adjusted. If a piston

cooling jet is not in alignment the piston cooling jet

must be replaced.

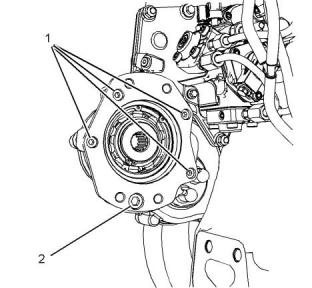

i03907005

Accessory Drive

(SAE “B” )

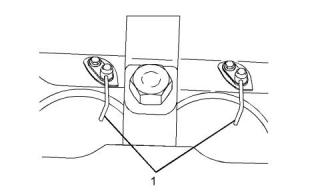

Illustration 71

g01352576

(1) Installed piston cooling jets

The valve must move freely. Torque for the bolt

................................................................9 N·m (7 lb ft)

Piston Cooling Jet Alignment

Illustration 73

g02148374

Typical example

(1) Tighten allen head screws to the following torque.

............................................................22 N·m (16 lb ft)

Illustration 72

g01352578

(2) Piston cooling jet

(3) Rod

(4) Cylinder block

(2) Tighten the allen head screw to the following

torque..................................................78 N·m (58 lb ft)

Use the following procedure in order to check the

alignment of the piston cooling jet.

1. Insert rod (3) into the end of the piston cooling jet

(2). Rod (3) has a diameter of 1.70 mm

(0.067 inch). Rod (3) must protrude out of the top

of the cylinder block.

2. Dimension (A) is 58.5 mm (2.30315 inch) and

dimension (B) is 13.5 mm (0.53150 inch).

Dimension (A) and dimension (B) are tangential to

the cylinder bore (4).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska